|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Minimal stress |

Minimal stress

20 February 2014

Pumping shear sensitive materials can be problematical; shear helps non-Newtonian fluids flow, but too much shear can cause temporary or even irrevocable damage, explains Wanner international.

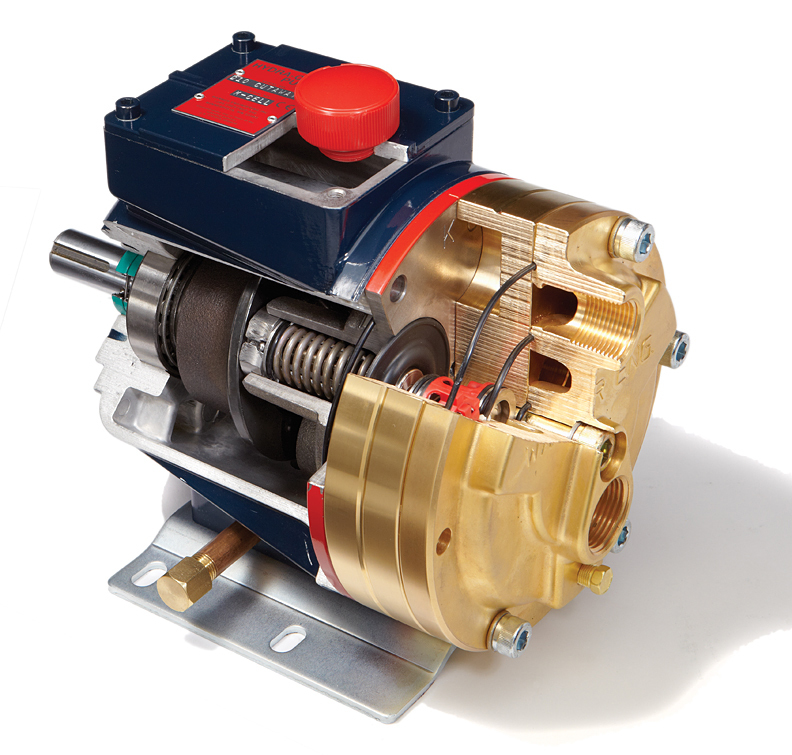

Its Hydra-Cell diaphragm pumps are said to impose only low levels of tangential stress on the pumped fluid making them suitable for pumping a wide range of shear sensitive materials such as polymers, paints, coatings, dyes, inks, latex solutions and technical suspensions.

As soon as the liquid leaves the vessel and enters the suction piping, it begins to shear as the liquid travelling through the middle of the pipe moves in relation to the pipe walls. Hydra-Cell pumps have no rotating elements in contact with the pumped liquid and no tight internal tolerances so they impose minimal tangential stress to cause shear.

"Having as many as five individual diaphragms in a single pump head, each with its own spring-supported horizontal check valves also helps minimise tangential stress," said Nick Herrington, Wanner's technical support manager. "The open area of each valve is large, relative to the volume of liquid being pumped by each diaphragm, so shear stress is minimised."

Hydra-Cell pumps are used by one of Europe's largest paint and coatings manufacturers for a range of transfer and dosing duties.