|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Online for productive launches |

Online for productive launches

14 March 2014

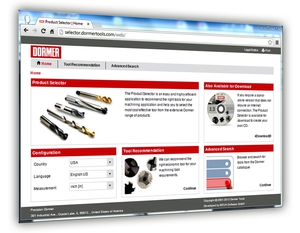

Visitors to Dormer’s stand will see a number of products developed to improve component production efficiency and can find details of the company's tools in its updated Product Selector.

Re-launched and updated for 2014, the product selector is a web-based application (www.dormertools.com) that provides guidance on the most effective machining solutions from the company’s ‘live’ database of more than 12,500 milling, drilling, threading and reaming products. It has been re-engineered to maximise ease of use, speed and compatibility with PCs running the latest versions of Windows.

As such, it aims to simplify the sometimes complex procedure of tool section, hopefully saving time and money that may otherwise be lost on materials or tools damaged through incorrect usage.

Another advantage of the online version is that it is automatically updated whenever a new product is launched.

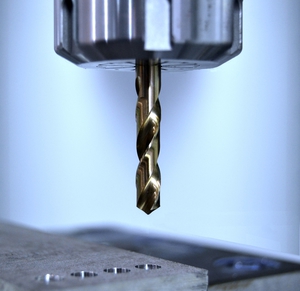

One key introduction to Dormer’s drilling range is the new A620. Recommended for use in a wide range of applications the high performance drill is particularly suited to machining stainless steels and HRSA (heat resistant super alloys).

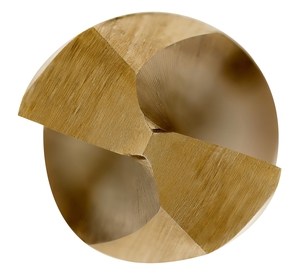

A key feature of the new range is its point geometry. This has been specifically developed to enhance all aspects of hole quality and positional accuracy. It is also said to be particularly advantageous when drilling materials that resist cutting and generate high temperatures, such as stainless steel.

In addition, the base material is a Cobalt-based HSS-E (M35), a premium grade of high speed tool steel which has been heat treated to retain hardness at elevated temperatures.

Ricky Payling, drilling product manager at Dormer, says: "The combination of material and geometry make the A620 an ideal choice for machining stainless steel and temperature resistant alloys.

"Not only is it manufactured from a very strong, wear resistant grade of steel but the point design minimises thrust forces when drilling, meaning the tool does not have to work as hard to penetrate the workpiece. This promotes both longer tool life and, due to reduced spindle forces, less wear and tear on the machine.” Stand 5248