|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cooling equipment | >Dehumidification solutions |

Dehumidification solutions

16 September 2014

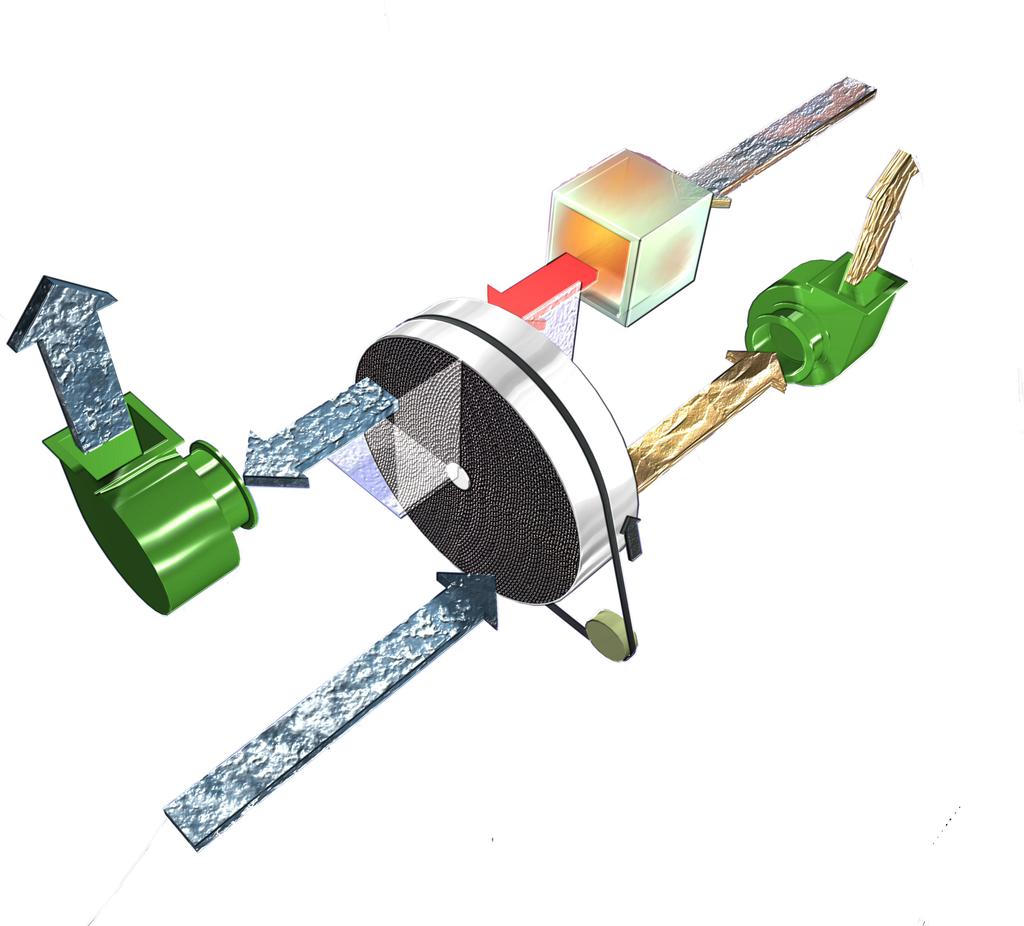

Humidity Solutions is promoting the use of desiccant rotor dehumidification systems to enable plastics moulding processes to operate at low temperatures, which boost productivity, without the risk of condensation. Effective dehumidification can also protect moulds against corrosion caused by high humidity.

"Moisture in or around thermoplastic or resinous raw materials can vaporise when temperatures rise, causing structural damage and aesthetic imperfections in end products,” explained John Barker of Humidity Solutions. "For maximum productivity however, moulds should be as cold as possible, which clearly increases the risk of condensation.

"A properly designed desiccant rotor dehumidification system makes it possible to control dew points on the surface of moulds while continuing to operate at lower mould refrigeration temperatures without compromising the quality of end products. It will also prevent damage to moulds during production and when stored,” he added.

Humidity Solutions offers a wide range of Fisair dehumidifiers, backed by a full design, installation and commissioning service to ensure that each solution delivers maximum benefits.

- Addressing low humidity

- The drive for data in remote monitoring

- Evaporative humidifier

- Humidity Solutions launches new Vapac Electrode Boiler

- Stable humidity improves productivity

- Humidity Solutions launch e-commerce site

- Steam distributor

- New factory for electrode boiler humidifier

- Humidity Solutions offers free CIBSE-accredited humidification webinar

- Stability at low humidity levels