|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Plastic composite router |

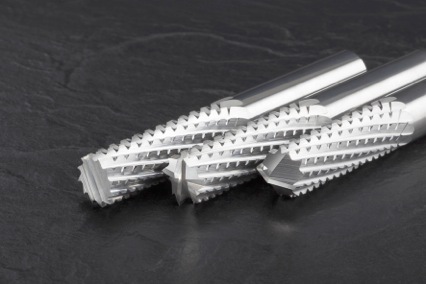

Plastic composite router

01 October 2014

Receiving its European launch at the Advanced Engineering 2014 show, SGS Carbide Tool (Stand D24) will unveil a new Plastic Composite Router (PCR).

Adding to the company’s high performance range, the Series 29 PCR is designed for machine routing glass reinforced composite materials, such as fibreglass and G10 epoxy fibreglass laminate, glass-reinforced plastic (GRP) or glass-fibre reinforced plastic (GFRP), as well as most other common plastic and non-metallic materials.

SGS produces this PCR range in a variety of length and diameter options as well as three different end styles; end mill, drill point and plain to meet the needs of manufacturers looking to trim, slot, profile and drill these materials. All sizes and end configurations are available from stock either uncoated or with diamond coating (Di-Namite) for maximum adhesion, superior wear, and increased tool life.

The optional Di-Namite diamond coating is an engineered application process providing maximum adhesion and smooth coating structure. Tolerances are tight for consistent batch-to-batch results and all Series 29 routers are manufactured from certified raw material substrates, designed for enhanced wear resistance in abrasive non-metallic materials, as well as optimum compatibility with CVD diamond application.

Using the latest in engineering design and grinding capabilities, the new Series 29 Plastic Composite Router is designed for efficiently machining composite materials and most common engineering plastics and non-metallic materials. This PCR has a number of advanced features and benefits compared to existing products designed for this material group. A radial chisel edge design provides better control of the fibre for improved surface finishes and longer tool life.

While the offset gashing of the four-flute mill style end is designed to provide four sharp corners versus the two corners of a conventional fibreglass router. With twice as many effective corners the Series 29 is particularly effective at machining to a right angle.