|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Materials | >Structural tribo-filaments for 3D printing |

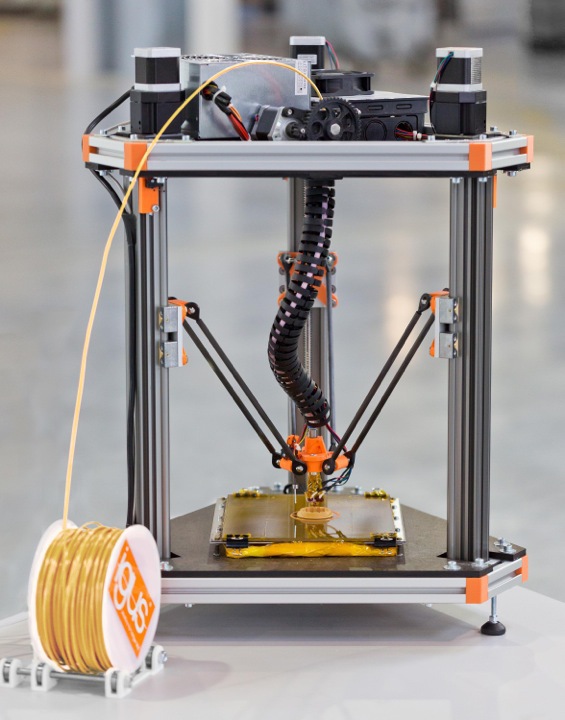

Structural tribo-filaments for 3D printing

10 November 2014

Tribopolymer expert igus has developed a structural plastic filament for use in 3D printing. Developed for engineers wishing to create prototype bearings or small batch samples for real-world tests, the igus tribo-filament is said to be up to 50 times more wear resistant than conventional plastic materials used for 3D printing.

Additionally, it is suitable for use with any 3D printer that has a heated nozzle and uses ABS filaments.

Available in two different materials; iglidur I170 and iglidur I180, with two different diameters; 1.75mm and 3.00mm, the tribo-filament is suited for a range of printing applications. iglidur I170 has a higher linear wear-rate than iglidur I180, allowing it to produce more robust products. iglidur I180 is more flexible than iglidur I170 and can achieve a higher bending radius for faster printing speeds as well as having a slightly higher processing temperature.

- Leadscrew module in stainless steel for extreme environments

- Medium voltage cable for long-travel crane installations

- Fibre optic cables: Benefits to industry

- Plastic additions

- Engineered Arts wins manus award

- Celebrating 21 years in the UK

- Bearing competition: Time to enter

- Articulated arms

- Long-lasting solutions for e-chain applications

- Bearings and cable management systems