|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Maintenance products | >Seals for extreme environments |

| Home> | Plant, Process & Control | >Seals and sealants | >Seals for extreme environments |

Seals for extreme environments

13 February 2015

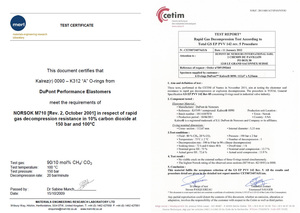

DuPont Kalrez 0090 (K-312 'A' O-rings) perfluoroelastomer sealing parts were developed to provide enhanced rapid gas decompression resistance in aggressive environments and have received '0000' rating in accordance with the NORSOK M-710 Rev. 2 standard and TOTAL GS EP PVV 142 specification.

These products, which are available from UK authorised distributor Dichtomatik, are said to provide the optimum balance of chemical, heat and mechanical properties for different chemical and oil and gas sealing applications.

Their performance has also been substantiated by further tests conducted at the Centre Technique des Industries Mécaniques (CETIM) of France, in accordance with the TOTAL GS EP PVV 142, Rev. 5 procedure. CETIM found DuPont Kalrez 0090 O-rings 113,67 x 5.33mm also fulfil the acceptance criterion of the TOTAL General Specification GS EP EVV 142 Rev.5. concerning O-rings used in the industrial valve industry. Kalrez 0090 is the latest in a family of DuPont perfluoroelastomer parts for the oil and gas industry that includes Kalrez Spectrum 6375 and Kalrez Spectrum 7090.

Kalrez 0090 products with enhanced RGD-resistant properties are currently in use at several major oil and gas companies. Many leading oil OEMs have also qualified Kalrez 0090 seals for use in surface and downhole valves, data logging drilling tools, packers, completion tools and mechanical seals.

The Kalrez 0090 seals feature high resistance to rapid gas decompression and are able to withstand attack by more than 1800 chemicals. They resist ageing in sour fluid, including multi-phase fluids containing high concentrations of hydrogen sulphide. In addition, they are said to retain high levels of elasticity, recovery and extrusion resistance even after long-term exposure to temperatures of 250°C and -40°C in high pressure environments.

Although Kalrez 0090 parts are a high hardness perfluoroelastomer, it remains elastomeric with low compression set under most aggressive HPHT environments.

The spectre of shrinking global oil reserves and the search for new, more difficult sources such as deep water and shale is well documented. Many new exploration sites challenge the oil and gas industry with increasing extraction pressures and temperatures, and by the presence of aggressive chemicals such as ammonia, carbon dioxide, hydrogen sulphide (sour gas), methane, and steam — exacerbated by the phenomenon of rapid gas decompression (RGD).

Often referred to as HPHT (high pressure/high temperature) environments, these more aggressive drilling conditions pose a new set of problems for suppliers and equipment operators within the industry because they create operating environments beyond the capabilities of some commonly used equipment-sealing elastomers.

Combinations of RGD, HPHT, and harsher chemicals can lead to premature seal failure, with the associated risks of costly financial, safety and environmental issues, and possibly resulting in plant premature shut downs. Because of this scenario the industry pressed for the establishment of a test standard to qualify non-metallic sealing materials. NORSOK standard M-710, Rev. 2, October 2001, developed by the Norwegian petroleum industry, has been widely adopted internationally as the benchmark of performance for any elastomer seal in critical oil and gas service. NORSOK certification for RGD is essential to qualifying performance of elastomer seals in HPHT and aggressive chemical environments, with the objective of reducing the risk of seal failure. TOTAL general specification GS EP PVV 142, Rev. 5, developed by TOTAL, is also widely accepted as an independent test of elastomer seal resistance to RGD in valve applications.

- For tough tasks

- Minimise flavour transfer

- Heat resistant seals last six years in thermo forming process

- Genuine seal of approval

- Local expert for food & beverage sealing solutions

- Sealing reliability

- Temperature resistant

- Clamp seals provide secure, hygienic tube connections

- Minimises risk

- Life Sciences addition