|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Materials | >Cleaner steels |

Cleaner steels

05 May 2015

Cleaner steels are opening up new design opportunities and extending service life for high performance parts, according to Ovako.

Today, more than ever, high performance components are expected to withstand higher loads over longer periods of time. Ovako will be demonstrating at Subcon 2015 how its clean steels can facilitate opportunities to rethink design solutions for improved safety, time and cost savings in a range of applications.

IQ-Steel (Isotropic Quality) has minimised the size of inclusions which increases its fatigue strength in all directions, while BQ-Steel is a more traditional choice for improved fatigue strength in demanding applications. Both can help customers in many industries to achieve lighter, stronger, more efficient and compact component designs.

IQ-Steel is a family of isotropic, ultra clean steels designed so that inclusions remain below a critical size with properties that match remelted steel. The pure and highly consistent quality is achieved without complex remelting processes that can add towards energy consumption and material price. The resulting isotropic properties are said to give two or three times the fatigue performance of conventional steel grades. IQ-Steel can upgrade the performance of gears, camshafts or safety-critical components that are subjected to high, complex and cyclic loading.

For high stresses in less complex load cases, high performance is available from the BQ-Steel family (Bearing Quality). The steels are said to have significantly smaller inclusions than conventional steels, which increases fatigue strength and creates new design possibilities in many high-stress applications.

"Some of the world’s most quality-oriented OEMs are already using our IQ-Steel and BQ-Steel grades in order to handle the strain of higher and more complex loads. We see great opportunities in expanding this scope for industries that are facing new design requirements and need lighter, stronger solutions,” said Göran Nyström, executive vice president at Ovako.

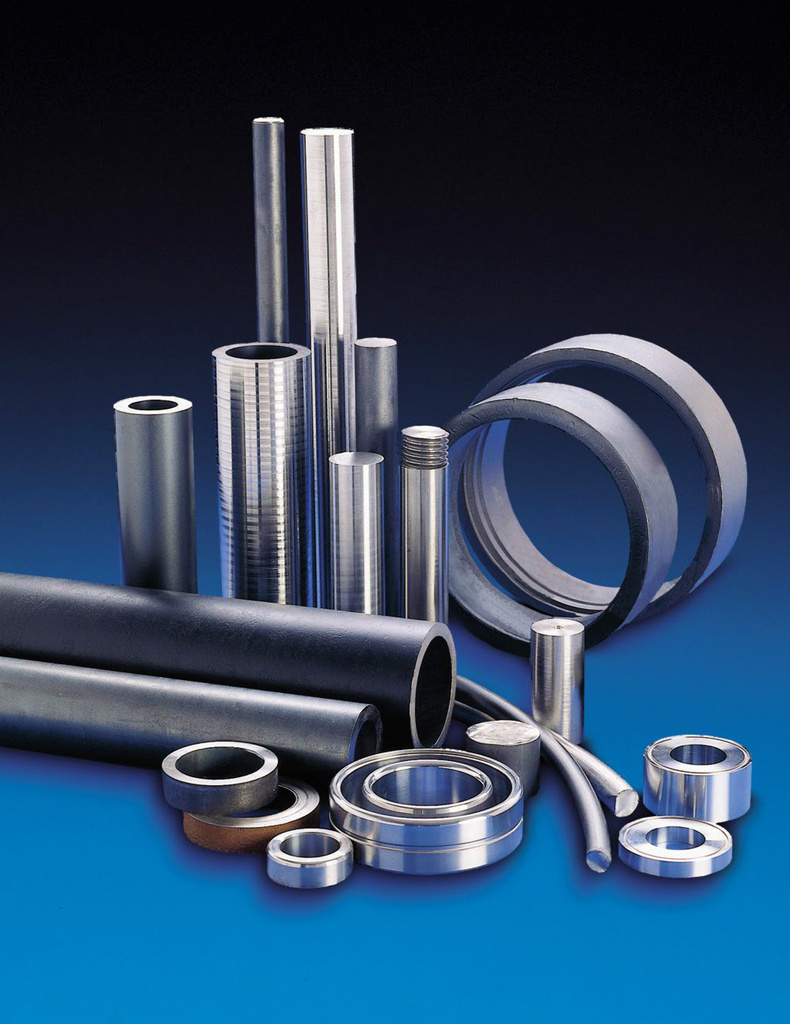

Working closely with customers Ovako optimises the steel performance for applications, producing cost effective material solutions in the form of bars, tubes, rings and pre-components. The centrally located UK Service Centre satisfies the supply of one-off or multiple piece product orders and operates a dedicated cut-to-length and material distribution services.