|

Edward Lowton

Editor |

|

3D printed gift fit for royalty

06 October 2015

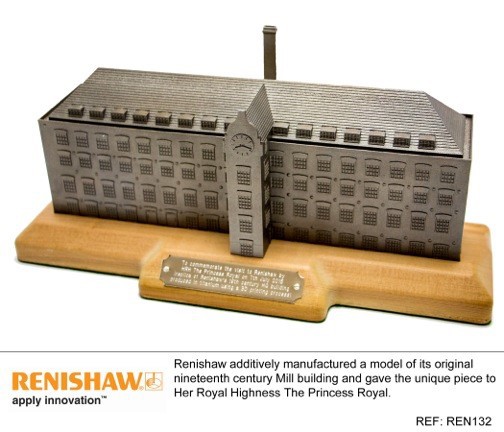

Renishaw has 3D printed a special gift fit for royalty. The company additively manufactured a replica of its nineteenth century Mill headquarters building and gave the piece to Her Royal Highness, The Princess Royal, when she opened Renishaw's new Innovation Centre and presented the company with its eighteenth Queen's Award.

The replica of the mill building was additively manufactured in titanium using Renishaw's AM250 machine. The part was produced in one build that took three days to manufacture before it was heat treated for stress reduction and after a further finishing process was mounted on a piece of treated pine taken from an original beam in the 1802 mill building.

"A few years ago we milled a replica of our Mill HQ building so we already had CAD designs that we could edit to optimise for the additive process," explained Jeremy Pullin, Rapid Manufacturing Manager at Renishaw. "This meant adding channels to allow powder to run off. It also gave us design freedom to be able to add minute definition - like roof tiles and window detailing.

"The original milled model was made from solid aluminium and produced in multiple parts - as you can imagine, it was quite heavy. The flexibility of the additive manufacturing process allowed us to produce the piece as one hollow part, reducing weight and production time."

Renishaw's new £20 million Innovation Centre at its HQ site near Wotton-under-Edge, Gloucestershire, gives the company an additional 153,000 sq ft of space for research and development and corporate services staff, as well as demonstration, training and conference facilities.

- New Renishaw testing facility puts packaging to the test

- Renishaw helps Irish Manufacturing Research (IMR) to advance aerospace optics manufacturing

- Additive manufacturing: Demonstrating design freedom

- Prime Minister tours R&D facilities

- Advanced engineering equipment

- Digital Manufacturing Centre & Renishaw collaborate

- Debunking the myths about 3D printing

- Renishaw announces passing of Sir David McMurtry

- Contact scanning system

- Production time halved for complex components