|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Contact scanning system |

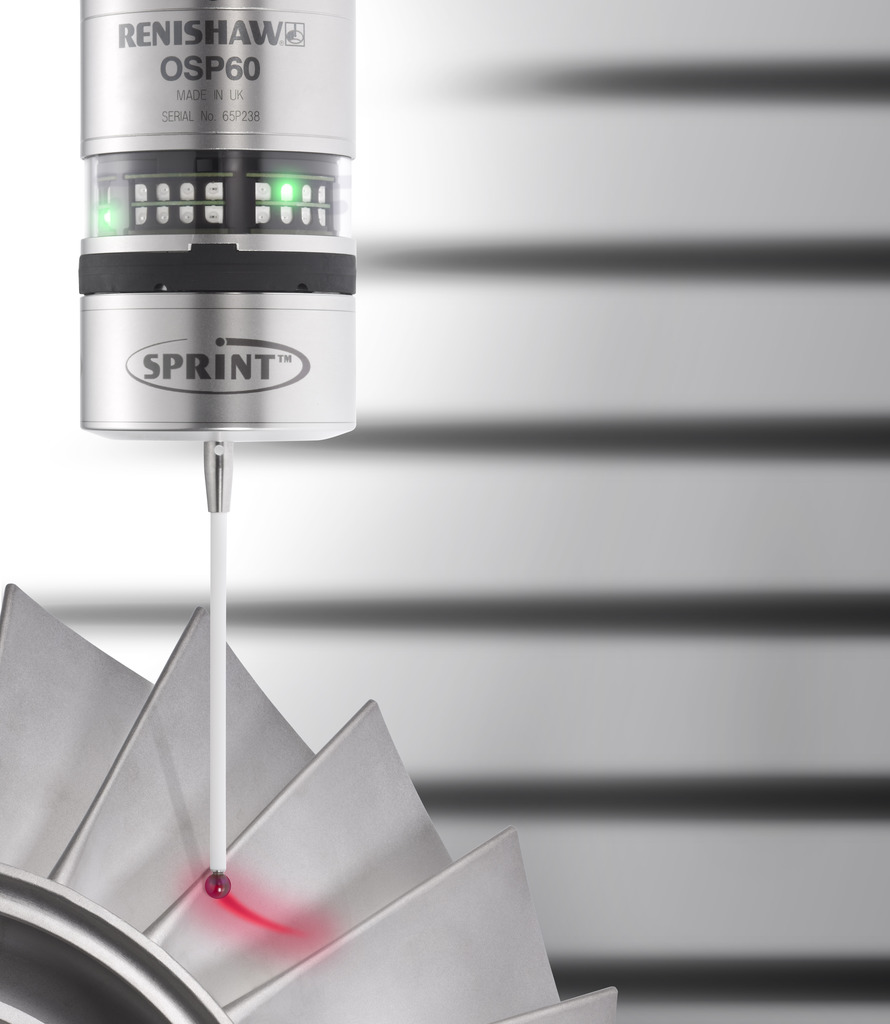

Contact scanning system

24 March 2014

Renishaw will be giving a UK exhibition premiere to its new Sprint high-speed contact scanning system for CNC machine tools at MACH 2014.

The Sprint system incorporates a new generation of on-machine scanning technology that Renishaw believes will deliver a step-change in the benefits of process control, enabling fast and accurate form and profile data capture from both prismatic and complex 3D components.

The system provides a high degree of capability for blade tip refurbishment and root blending applications. The high-speed measurement of blade sections, coupled with high data integrity (even on leading and trailing edges) ensures the indication of true part condition leading to an adaptive machining capability. Automated routines, such as set-up, blade alignment, blade scanning and data collection are said to result in accuracy and cycle time improvements over touch-trigger systems.

For multi-task machining applications, the Sprint machine tool scanning system offers users completely new process control capabilities, including highly repeatable diameter measurement cycles. By employing master part comparison, the Sprint system becomes an 'active' control enabling measure-cut processes to be automated for accurate diameters on large parts. This capability can result in the size of diameters being automatically controlled to within a few microns of tolerance. Measurement functionality such as part run out, machine centreline and circularity, also serves to significantly enhance the manufacturing capability of multi-tasking machine tools.

Additional functionality offered by the SPRINT system provides a rapid health-check of a CNC machine tool's linear and rotary axes in seconds, making it possible to implement a daily machine monitoring regime with little or no operator involvement.

Stand 5730

- Production time halved for complex components

- Focusing on position feedback

- Navigating market changes: How Renishaw is driving innovation and efficiency

- Debunking the myths about 3D printing

- Renishaw announces passing of Sir David McMurtry

- New Renishaw testing facility puts packaging to the test

- Advanced engineering equipment

- Renishaw helps Irish Manufacturing Research (IMR) to advance aerospace optics manufacturing

- Next generation of digital encoder

- Precision engineering