|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Advanced engineering equipment |

ARTICLE

Advanced engineering equipment

04 March 2013

Renishaw will be exhibiting its range of advanced engineering technologies at Southern Manufacturing. On show will be the companys versatile gauge, Equator, which rapidly collects thousands of data points for the comparative measurement of high volume manufactured parts.

Renishaw will be exhibiting its

range of advanced engineering

technologies at Southern

Manufacturing. On show will be the

company's versatile gauge, Equator,

which rapidly collects thousands of

data points for the comparative

measurement of high volume

manufactured parts.

Also on show, the AM250 laser melting system uses an additive manufacturing process that is capable of producing fully dense metal parts direct from 3D CAD, using a highpowered fibre laser.

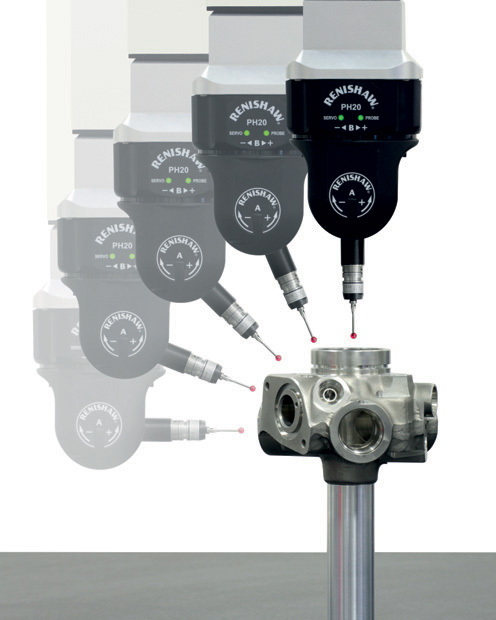

Renishaw will also be demonstrating the PH20 5-axis touch-trigger system for coordinate measuring machines (CMMs), which increases touch-trigger probing throughput up to three times, using fast, infinite, rotary positioning and unique 'head touch' capability for high-speed point capture. Stand Q48

Also on show, the AM250 laser melting system uses an additive manufacturing process that is capable of producing fully dense metal parts direct from 3D CAD, using a highpowered fibre laser.

Renishaw will also be demonstrating the PH20 5-axis touch-trigger system for coordinate measuring machines (CMMs), which increases touch-trigger probing throughput up to three times, using fast, infinite, rotary positioning and unique 'head touch' capability for high-speed point capture. Stand Q48

MORE FROM THIS COMPANY

- Next generation of digital encoder

- Precision engineering

- Navigating market changes: How Renishaw is driving innovation and efficiency

- Renishaw apprentices win prestigious industrial robotics contest

- Automating additive manufacturing

- Focusing on position feedback

- Production time halved for complex components

- Renishaw helps Irish Manufacturing Research (IMR) to advance aerospace optics manufacturing

- Digital Manufacturing Centre & Renishaw collaborate

- Contact scanning system

OTHER ARTICLES IN THIS SECTION