|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Focusing on compressed air efficiency |

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >Focusing on compressed air efficiency |

Focusing on compressed air efficiency

03 October 2016

Gardner Denver will be showcasing the latest technology to optimise compressed air efficiency at the Energy Management Exhibition (EMEX) 2016 (16th to 17th November, Excel, London).

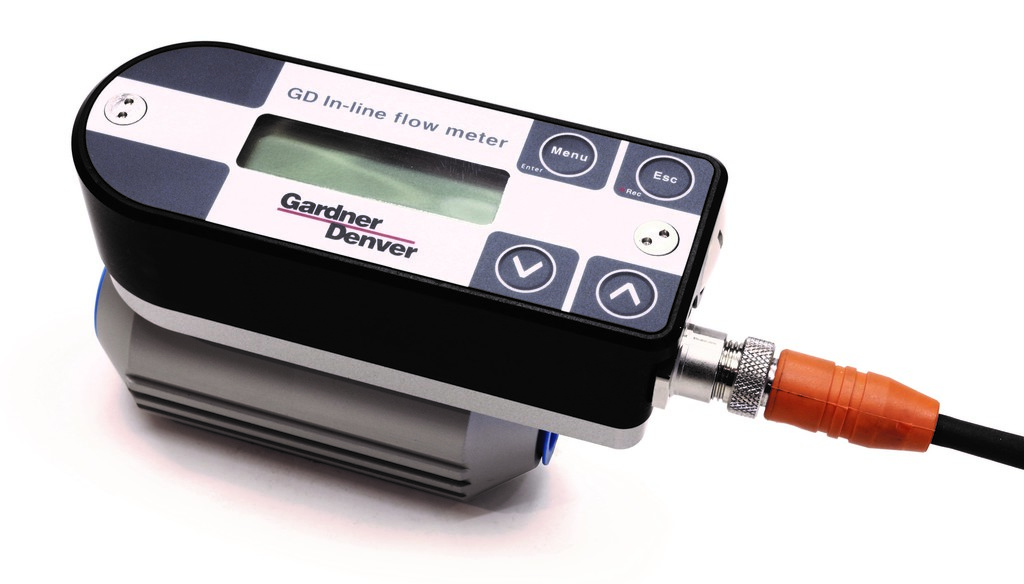

Its new insertion and in-line flow meters are designed to ensure that flow, pressure and temperature can be monitored at a glance, ensuring any air leaks can be quickly identified and remedied. Only one flow meter is needed to measure each of these factors, simply by fixing the equipment directly to the pipework.

Gardner Denver will also exhibit its variable-speed compressor range. Keith Findlay, Northern Europe aftermarket sales manager, says: “The CompAir L-RS series variable speed machines can help customers to achieve the maximum efficiency possible. They have a premium efficiency inverter that can reduce running costs by up to 35%, while the outstanding reliability makes them an ideal choice for large capacity applications.”

- Latest air filtration & water separation solutions

- Service boost

- Free seminar on compressed air and vacuum efficiency

- Energy savings for furnishings firm

- Boosting compressor efficiency

- Water-cooled, oil-free compressor

- Kicking downtime into touch

- Vacuum pumps: Be air aware

- Air of the unreal

- Compressed air solution for the aquaculture market