|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Quick change chuck jaws |

Quick change chuck jaws

11 October 2016

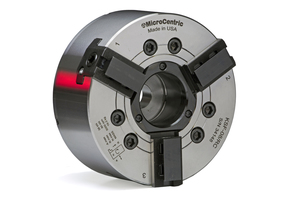

Now available from UK and Eire agent, Leader Chuck Systems, MicroCentric KSF RC high precision power chucks are available in two diameters and feature MicroCentric’s Rapid Change Jaw System that can reduce changeover times on CNC lathes and turning centres.

Managing Director, Mark Jones, says: “Quick-change chuck jaws make unarguable sense in any high variation workshop production scenario. Simply put there are only two states a machine tool can be in that really matter to any workshop: in production, making parts, or not. When a machine is making parts, it is making money. When a machine is not making parts, it is costing money. Therefore any reasonable investment that helps a machine make parts more of the time is going to improve business performance. These new MicroCentric chucks fit the ‘reasonable’ investment profile perfectly.”

The KSF-08/RC is a 210mm diameter chuck with a 66mm through hole, while the larger KSF-10/RC is 254mm diameter with an 82mm through bore. Both are rated up to 5000 rpm and can be specified with A2-5, A2-6 or A2-8 spindle mounting plates.

Featuring a boltless design the rapid change jaws on the new KSF range offers a full jaw area for clamping. Supplied soft as standard, with hard jaws available as an option, they can be exchanged in seconds but remain precise. The KSF chucks have a repeating accuracy of 0.0025 mm, such that when top jaws are finished machined on the chuck MicroCentric guarantee that parts will run within 2.5 micron radial and lateral TIR if the top jaws are not removed from the chuck. After machined top jaws are removed and then replaced onto the same base jaw they were machined on, a maximum runout of 0.025mm TIR is guaranteed. A graduated scale engraved into the master jaw facilitates quick precise positioning of the top jaws during changeover.

If a higher level of accuracy is required after top jaws are changed, the radial runout of KSF chucks can be adjusted. Since the spindle adapter mounts to the spindle nose and the chuck then mounts to the adapter plate, the radial runout of the clamped part can be corrected to between 10 and 20 micron by a special MircoCentric feature. The chucks feature four radial adjusting screws on the outer diameter of the chuck body to achieve this and once the runout of the part has been adjusted the repeatability of the chuck is assured for subsequently clamped parts.

Precision fit master jaws minimise lift with a wedge design securely pulling the jaw down onto precision serrations. Pitched at 1.5mm, the serrations aid speedy location of each of the three jaws, while hardened chuck bodies, actuators and master jaws ensure long-term accuracy and performance.

Mark Jones puts the investment into perspective: “Say your machine time is charged out at a very reasonable £40 per hour, and it takes half an hour to change jaws on average. That means a jaw change costs you £20. However, MicroCentric’s Rapid Change Jaw System cuts the time to under five minutes, so you get back at least an extra £15 worth of machine time with each jaw change, and that is per machine. Add up all the jaw changes over the course of a year, and you will be surprised just how big that number gets.”