|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Reduced costs & improved reliability |

Reduced costs & improved reliability

02 April 2017

When Thames Water (TW) was having problems with its diaphragm pumps for dosing ferric sulphate at its Hogsmill sewage treatment works, SEEPEX was able to provide a solution that was easy to install and significantly reduced running costs.

Probelms ranged from sticking ball valves, to diaphragm failures which required replacement every six months. After discussions with SEEPEX, TW engineers installed a progressive cavity (PC) dosing pump which is said to have given TW a reliable alternative to diaphragm dosing pumps as well as providing the following advantages:

- No ball valves to stick – avoiding frequent pump failures

- Self-priming, offering suction lifts up to 9m – no need for pump priming procedures

- Accurate, low pulsation linear flow, directly proportional to pump speed

- Variable frequency drive with local control – no need for calibration pots

- Corrosive and abrasive products can be handled with discharge pressures up to 48 bar

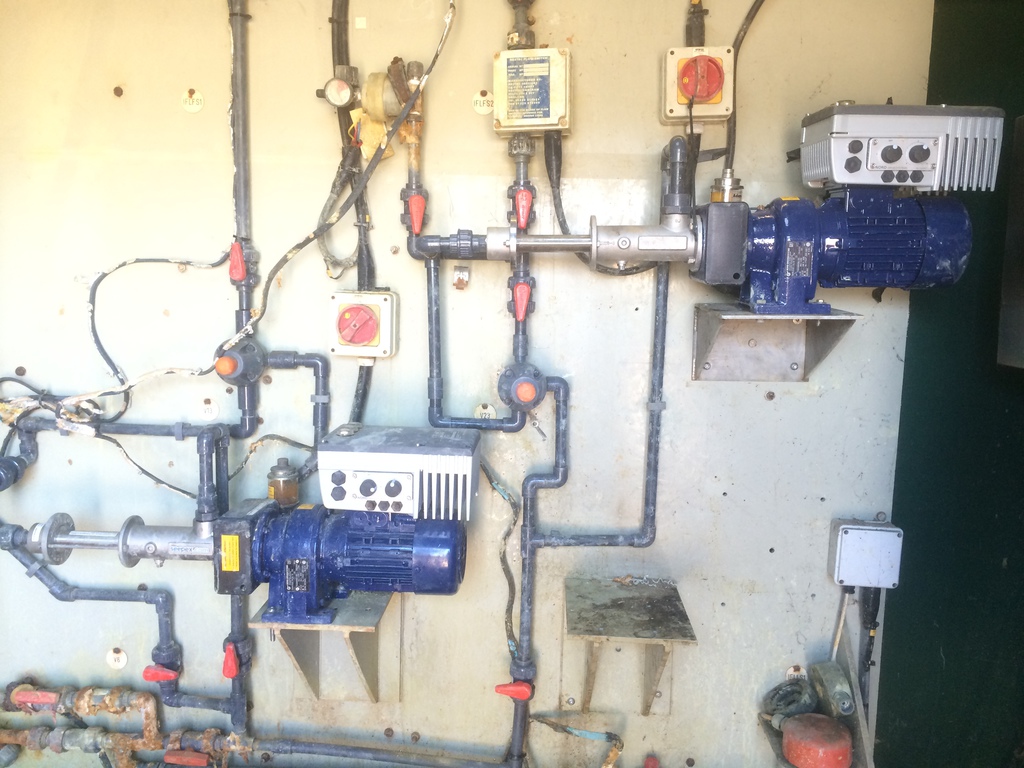

TW engineers installed the first SEEPEX pump in early 2014 and the pump has operated for over 2 years without maintenance or breakdown. A second pump has since been installed, and both pumps are installed in the same secure cabinet as the diaphragm pumps.