|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Plastic bearings make the grade |

Plastic bearings make the grade

03 August 2017

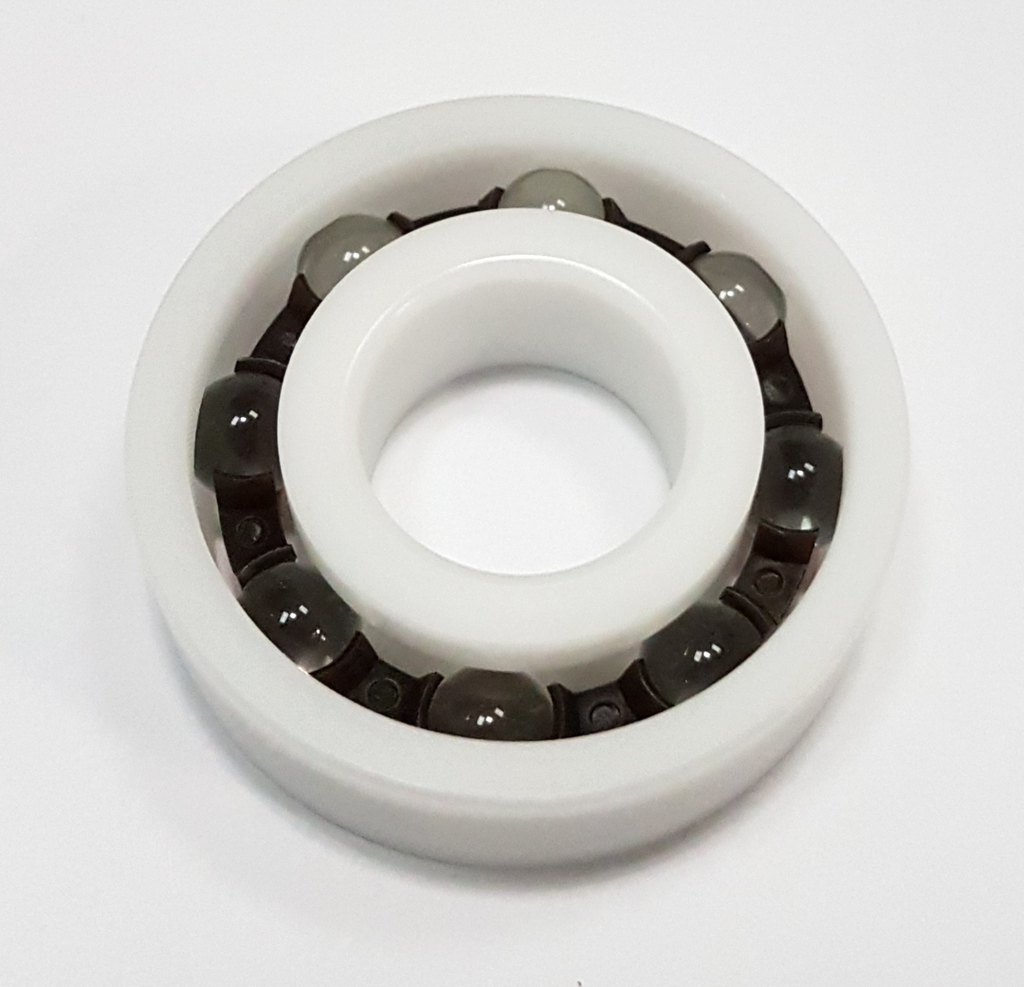

Miniature and specialist bearings provider, SMB Bearings, has launched a range of corrosion resistant, non-magnetic plastic bearings.

Bearings used across the chemical, pharmaceutical and food industry need to be able to handle corrosive fluids and materials. Those used in food applications need to cope with regular wash-downs and must also meet strict hygiene standards. Plastic bearings are non-corrosive and are usually unlubricated which makes them ideal. The standard range are acetal resin with glass or 316 stainless steel balls but they can be offered in a variety of materials from PEEK to PVDF to cope with a wide range of corrosive fluids.

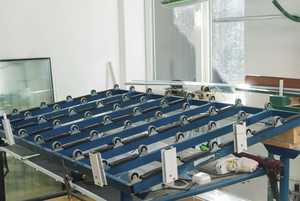

As the material is relatively soft, plastic bearings should only be used in low load applications. They are normally used in lower precision applications, such as conveyor rollers and trolleys.

- Japanese bearings find UK base

- Stocking up on specialist bearings

- Material choices for durable bearings

- Bearings chosen for robotic exoskeletons

- Supporting the surge in global shipping

- What makes a corrosion resistant bearing?

- Robot accuracy: Importance of bearings

- Invitation to observe bearing relubrication

- Small batch relubrication service

- SMB Bearings receives safety star award from Avetta