|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Pedal to the metal (cans) |

Pedal to the metal (cans)

21 September 2017

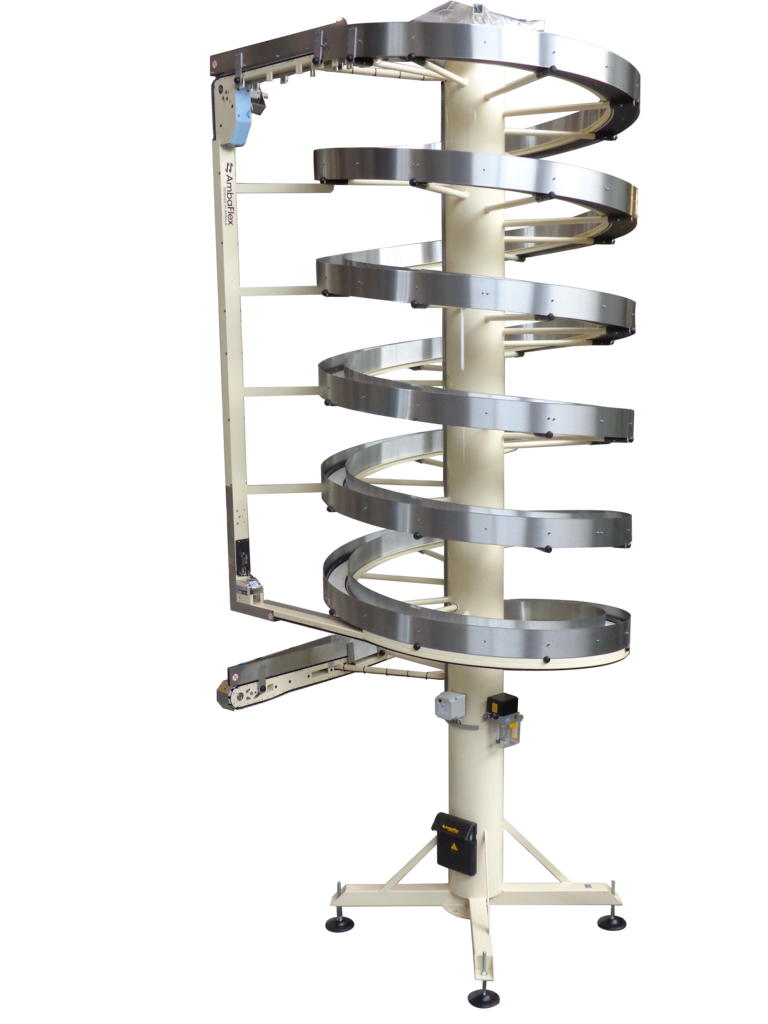

When a French customer of Ambaflex wanted to upgrade its factory equipment and maximise line efficiency, it chose to integrate SpiralVeyor technology in combination with an accumulation table.

This particular line runs over 100m/min, transporting up to 800 cans per minute of different sizes, down the AmbaFlex spiral conveyor to the accumulation table 4m below. With this kind of speed requirement, conventional methods like a platform elevator or wedge elevator were out of the question.

In addition to being able to safely reach those speeds without the risk of damaging the product and maintaining a low cost of ownership, the SpiralVeyor saved enough room to fit in the accumulation table. This setup greatly increased the throughput, saved valuable space and reduced costs at the same time.

The SpiralVeyor in question holds a 38m long and 100mm wide belt. It has special product guides making sure the cans stay stable throughout their journey down, even at high speeds. The patented Tripple E low friction technology reaches these speeds while ensuring a long, low-maintenance life.