|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Monitoring and targeting | >Improving the safety and efficiency of hydrogen production and carbon capture |

Improving the safety and efficiency of hydrogen production and carbon capture

19 June 2023

With potentially hundreds of new hydrogen and carbon capture plants set to be built around the world in the coming years, the choice of instrumentation has a key role to play in ensuring processes are both safe and optimised for efficient production, explains Neil Jackson

INSTRUMENTATION PLAYS an essential part in keeping any process plant safe and optimised for efficient production, while also helping to ensure regulatory compliance. That's certainly the case for hydrogen.

Due to its molecular size, hydrogen is notoriously difficult to keep in the places we want it to be. It's difficult to detect and extremely dangerous if it does get loose.

As for carbon dioxide, while not explosive, it is heavier than air and stays very close to the ground, doesn't disperse easily and, of course, can be fatal.

Therefore the right selection of instruments is critical, particularly if they're in-line devices for pressure, temperature or flow, for example. However, first, it’s helpful to look at why we’re seeing a massive upscaling of the utilisation of hydrogen.

Rising hydrogen usage

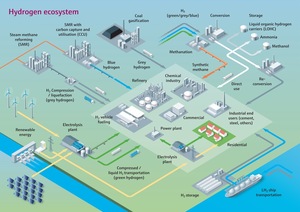

As industries seek to decarbonise, hydrogen can be used in a number of different ways.

It can be used as a feedstock and alternative to natural gas for industrial production in petrochemical facilities, displacing to some extent the hydrocarbons which are used today. It may also be used for direct firing of kilns and furnaces.

It will be added to the existing (gas) National Transmission System, reducing the amount of methane, in turn reducing CO2 emissions as we heat our homes or in lighter industrial applications.

Perhaps where it will be most commonly used is as we look to electrification, as a way to decarbonisation, because hydrogen can be used to generate electricity.

As we go towards 2050, electrification has a vital role to play in helping us decarbonise our transportation and industry.

Much of that electricity will be generated from renewables, such as wind and solar. But the question remains: What happens when the wind doesn't blow and the sun doesn't shine? Yet our demand for electricity will be around 3x higher than it is today. Hydrogen will potentially be used to address that issue.

Yes, batteries will be used to store some of the electricity generated from renewables. However, they do not offer a complete solution, as the size and the number required make it impractical from the perspective of total storage required. Nor are batteries particularly environmentally friendly. So that's where hydrogen comes into play.

Blue and green hydrogen

Here we come to blue and green hydrogen. Green hydrogen is produced from renewable energy sources, using an electrolyser process. Blue hydrogen is created from what is essentially a refinery process – reforming natural gas into hydrogen.

From an electrolysis standpoint, we all probably remember the experiment at school where we had a cathode and an anode placed in a test tube containing water. We pass a direct current through that and the result is that we change some of the water into oxygen and hydrogen. We'd test for the hydrogen using a lit taper to hear that 'pop'.

Today's electrolysis plants and electrolysers are, in essence, a more sophisticated version of that experiment.

With the technology available today there are principally two types of electrolysers in use. There's an alkaline-based unit which uses potassium hydroxide and water as the electrolyte. That is fed into both sides of the electrodes, current is passed between them and, because there is a membrane between the two, the oxygen transfers and the hydrogen doesn't and can therefore be recovered.

The advantages of the PEM process

Meanwhile, with a proton-exchange membrane electrolyser, the process is reliant only on water, which is purified and demineralised but doesn't require any other additives. It's a simpler process to the alkaline one, but it does require the use of a noble metal to act as a catalyst to create both the hydrogen and oxygen, increasing the cost.

As a technology, the PEM process is far more efficient than the alkaline process and can be switched on and off far more quickly. This obviously lends itself to a situation where the electrical supply is based primarily on renewables and solar.

Blue hydrogen production

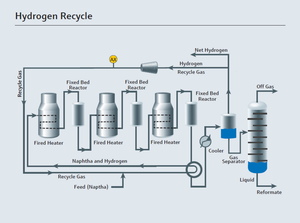

This is essentially a refining process where natural gas is mixed with steam to produce CO + H2 in the gas heated reformer (GHR). This is combined with O2 in the autothermal reformer to produce CO2 + H2. The CO2 is removed and the H2 is purified in the pressure swing absorber to a purity of >99%.

An interesting new method of production is the use of thermal plasma electrolysis which uses plasma torches created by an electric field to split the hydrocarbons. The result is hydrogen and only solid carbon with no CO2.

The role of instrumentation

Instrumentation plays a vital role in many different stages of these processes. Below are a few examples where Endress+Hauser instrumentation has been utilised:

1. Instrumentation for electrolyser

2. Trace moisture measurement in H2

3. Instrumentation in steel production

4. H2 blending in gas turbines

5. Carbon capture and storage

1. Instrumentation for electrolysers

In this instance, Endress+Hauser solutions were used at a hydro powerplant in Rheinfelden, Germany. Part of the electricity generated is feeding an electrolyser, which has been in operation to produce green hydrogen since 2019.

What's critical here is water treatment and purification. The water source for the alkaline electrolyser is drawn from the river Rhine. It's essential that it's treated correctly and to the right purity levels for use in the electrolyser.

The measurement technology used here includes level control of the filter beds to optimise performance and flow metering to ensure the correct delivery of water to the treatment plant. We also measure the pH, conductivity and turbidity, looking at the concentration of solids in the water supply.

2. Trace moisture measurement in H2

A critical factor is the quality of the hydrogen generated, ensuring in particular that the moisture content is within specification. One of the devices we use here is a tunable diode laser absorption spectroscopy (TDLAS) analyser. This measures the gas's absorption of the light generated by the laser, which varies depending on its moisture content.

In so doing, we can get down to very low trace levels of moisture, well into the parts per million or even parts per billion levels. And that's particularly critical if that hydrogen is being used in fuel cells. With that application it's essential that the moisture level of the hydrogen is kept well within specification.

3. Instrumentation in steel production

Turning to the steel industry, a traditional blast furnace uses approximately 500 kg of blast furnace coke gas and pulverised coke to produce one ton of pig iron. The coke and coal are required to form the chemical reaction within the blast furnace.

In this application, Thyssenkrupp is using green hydrogen injected directly into the blast furnace to reduce the amount of furnace coke gas required, which in turn reduces the amount of CO2 emitted during the process.

Currently, Thyssenkrupp is piloting this on one tuyere of their blast furnaces and is gradually increasing the amount of hydrogen that is utilised. It is hoped to achieve around a 20% reduction in CO2.

Clearly, the safe operation of the plant is critical in this case. Tight control of the flow of hydrogen is managed through the use of the Prowirl vortex flowmeter and Cerabar pressure and Moduline temperature transmitters.

In a similar application, Dillinger Steel Works blends hydrogen into its coke oven gas, prior to injecting it into the blast furnace. This uses a similar quantity of vortex flowmeters as well as deploying close to 200 pressure transmitters as a vital part of the safety system for the coke oven batteries. The green hydrogen used in this application is generated from an electrolyser located next to the plant.

4. H2 blending in gas turbines

This leads us to another application, this time with hydrogen being blended into natural gas. In this case, the gas was fed to a gas turbine. The use of hydrogen helps reduce the amount of methane contained in the natural gas, in turn reducing the plant's CO2 emissions.

In this application, the measurement of the hydrogen flow is carried out using a Promass Q Coriolis meter. This is used to control the ratio of hydrogen to natural gas. We are also using a Raman analyser to perform an online analysis of the composition of the hydrogen and natural gas blend to ensure consistency prior to the fuel reaching the gas turbine.

Beyond providing the concentration and composition of a single stream of gas, the Raman analyser can be connected to up to four probes, allowing it to provide data on multiple processes simultaneously. For example, you could monitor the blend of the gas, but also both the hydrogen and the natural gas separately before they are blended.

Another benefit of using a Raman analyser is that it's a non-extractive process. The probes are in-line, so it's not necessary to remove any of the gas as part of a sample. Therefore it's emissions-free.

Additionally, compared to a traditional gas chromatograph approach to analysing gas composition which has a very slow cycle time, a Raman analyser is very quick to detect any changes, making it ideal for alarm applications and enabling action to rapidly be taken to adjust the gas composition or, if necessary, safeguard the plant.

5. Carbon capture and storage (CCUS)

Turning to carbon capture, our involvement with CCUS projects dates back to 2008, during the design stage of the MONGSTAD Technology Centre in Norway.

Endress+Hauser instruments were selected for a number of the major units including the amine plant and the power and steam generation plant. The applications included flow, level, pressure and temperature, while a range of analytical devices were applied.

MONGSTAD uses an amine-based CO2 capture process. Flue gas is received into the contactor tower where it is absorbed into the amine solution. This rich amine is then passed through to the regenerator where the CO2 is stripped out and the lean amine is fed back into the absorber tower to begin the cycle again. The CO2 is subsequently dehumidified and can be sent to storage.

Traditional carbon capture plants are really designed to run continuously. But optimising them can be quite challenging. If the temperature is too low, it results in insufficient CO2 being extracted from the rich amine solution as it passes through the regenerator. Alternatively, if the temperature is too high, while it increases the amount of CO2 which is extracted from the process, it leads to a degradation of the amine solution, shortening the time before the solvent is replenished or replaced and increasing operating costs.

In order to optimise production, we used a similar Raman analyser to the one used for the blending of hydrogen into natural gas. This monitors both the rich and lean amine to determine the CO2 content in both parts of that process. That enables the plant to be started, brought online and optimised in a very short timescale. That's particularly important when we consider the carbon capture plants used in association with gas turbine generators being run up to meet a surge in demand.

The traditional way of analysing the CO2 content of rich and lean amine is to do an offline titration analysis. However, this can take around 30–40 minutes. By contrast, if we use a Raman analyser, we're able to do that test online and very quickly, while also looking at other data such as variation of solvent quality and degradation, minimising amine wastage.

At Endress+Hauser, we believe that experience and know-how are key when it comes to the design, manufacture and selection of instrumentation which is destined to be installed on the potentially hundreds of new hydrogen and carbon capture plants to be built over the coming years.

But the applications discussed here only offer a brief snapshot of the Endress+Hauser portfolio and capabilities. It’s important to highlight that we not only provide instruments for carbon capture and hydrogen but also serve many different industries.

Neil Jackson is oil and gas industry manager at Endress+Hauser UK

For more information:

Tel: 0161 286 5000

- Thermometer portfolio

- Two-wire technology

- Meters, loggers and software

- Online process engineering training

- Collaborating on calibration

- Simple,scalable automatic meter readings

- Avoiding errors when designing safety systems

- Digitalisation helping to drive growth

- Technical support from Endress+Hauser

- Efficient utilisation of unused device data