|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Interroll receives sorter order for French postal hubs |

Interroll receives sorter order for French postal hubs

09 December 2019

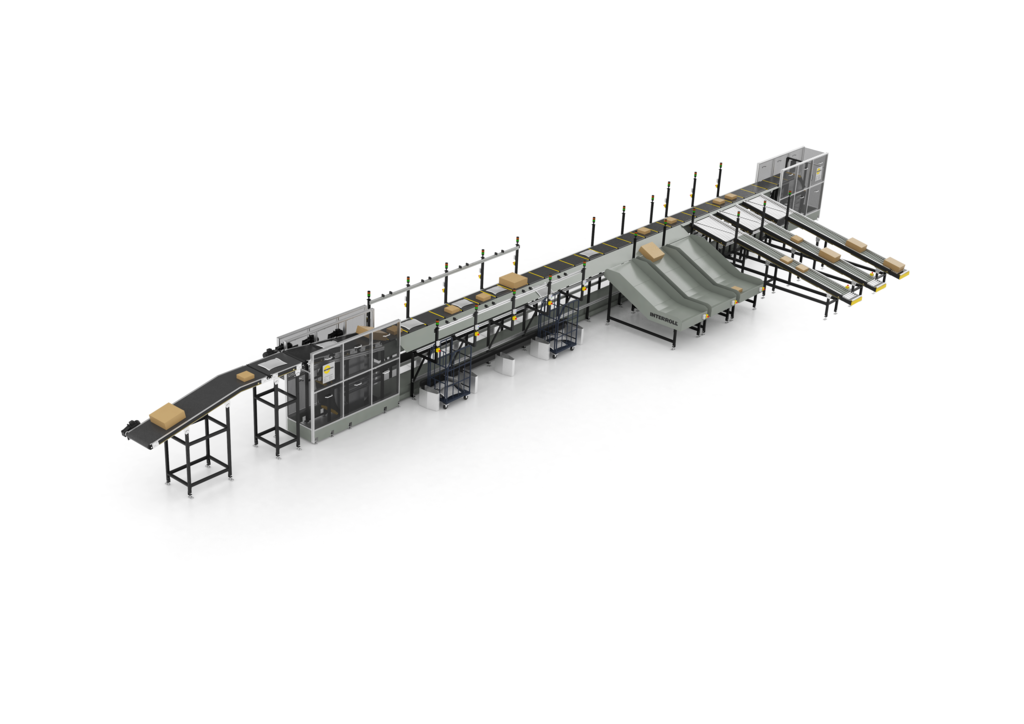

Systems integrator, Actemium Lyon Logistics, and Interroll will supply three sorters for French postal companies, La Poste, DPD and Viapost. The order will include the 400th Interroll sorter.

Three of the sorting systems will be installed for three different entities within the La Poste group in France: La Poste Roissy Hub (August 2020 - Roissy), DPD (July 2020 - Billy-Berclau) and Viapost (June 2020 - Argonay).

The rise in e-commerce is leading to a steady increase in parcel volumes worldwide, more diversified packaging, as well as higher expectations on the delivery time. These trends are posing new challenges for La Poste's logistics companies, in particular when it comes to the processing and sorting of packages.

To meet these challenges in a flexible and efficient way as an integrator, Actemium Lyon Logistics developed a concept to apply the latest conveyor and sorting technologies as well as state-of-the-art warehouse control systems solutions for the three sorting platforms.

"These new orders came follow many years of successful collaboration between Actemium Lyon Logistics and Interroll," says Nicolas Jaffeux, Postal and Express Department Manager, Actemium Lyon Logistics, and Bruno Maisonneuve, Business Unit Manager of Actemium Lyon Logistics. “Actemium is an active partner in Interroll’s ‘Rolling On Interroll’ program.”

Interroll offers horizontal and vertical crossbelt sorters for fully automated sorting processes in the courier, express and parcel service providers market. Throughput rates of 2000 to 15,000 units per hour make the Interroll Crossbelt Sorter a highly efficient sorter for goods of all types.

With the addition of a new infeed module, Interroll has expanded its modular platform solutions for highly efficient material flow. It is designed to work with Interroll crossbelt sorters. The new infeed modules combine higher infeed speeds with reduced space requirements to offer a substantial potential increase in goods flow in automatic sorting systems. In addition, their very low noise level guarantees a comfortable working environment for operators working nearby. Finally, the mechanical design of Interroll's mechanical crossbelt sorters limits energy consumption to a strict minimum, while offering very high availability and flexibility in its use, ensuring a low environmental footprint.

"With Interroll's flexible sorting solutions and the collaboration with Actemium Lyon Logistics, we look forward to further contributing to the performance and flexibility of postal companies worldwide," says Gilles Calvez, Managing Director of Interroll France.

- Modular conveyor platform

- Wheely versatile

- Interroll Ltd becomes latest AMHSA member

- Tapered elements secured from inside

- Pallet control unit enables zero-pressure pallet

- Modular drum motors

- Motorised drive solutions

- Interroll showcasing conveying and sorting solutions

- Push back system

- Modular drum motors