|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Valves and actuators | >A modern solution to steam conditioning |

A modern solution to steam conditioning

16 February 2024

Technical innovation and leading-edge valve design has improved the conditioning of superheated steam used in power generation and other essential industries, says Mark Wheat

MANY INDUSTRIAL activities rely on steam for their processes, including power generation plants, refineries, and paper mills. The means to generate energy using steam have been understood for centuries. The basic principles, using a boiler, steam turbine and generator, remain largely unchanged. However, the pressures and temperatures involved have increased considerably.

Operational challenges

A steam power plant essentially uses a boiler to generate steam at high pressure and high temperature. A steam turbine converts the heat energy of steam into mechanical energy, and a generator then converts the mechanical energy into electric power.

Water boils at 100ºC under normal atmospheric pressure [0.101 MPa]. As pressure increases, the boiling temperature of water also increases. When the pressure is increased to 22.12 MPa, and at a temperature of 374ºC, water is directly converted into steam. This is called the critical point. Pressure above this critical point, with a temperature equal to or more than 593ºC, is called ultra-supercritical pressure.

Handling superheated steam at these pressures and temperatures places enormous strain on flow control equipment. Inadequately specified valves could lead to inefficiencies through leakages and unplanned outages. What the 21st century required was a valve that could deliver operational reliability and withstand the extreme operating conditions within modern power plants - particularly during plant start-up, shutdown and turbine trips.

A 21st century solution

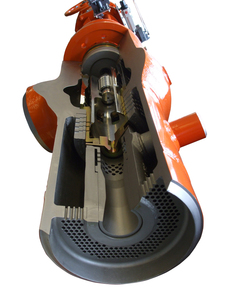

The DSCV-SA (Direct Steam Converting Valve - Steam Atomization), addresses the issues encountered by older, base load designed bypass valves when employed on modern high frequency, rapid ramp rate plants. Key to the DSCV-SA’s performance are a number of unique technical innovations developed following extensive consultation with power generation customers.

Unlike conventional turbine by-pass valves, the DSCV-SA is designed to use high-pressure balance rather than low-pressure balance. This eliminates risk of wear, damage or breakage relating to piston rings and balancing systems, which are a major problem with traditional valves.

When an open command signal is received, the DSCV-SA actuator retracts and the pilot plug is the first to open. This allows P1 steam to flood through the large pilot plug port to the underside of the main plug, which in turn balances it and reduces the actuation thrusts required.

In traditional low-pressure or P2 balancing designs, auxiliary balancing seals such as piston rings and close tolerance sealing surfaces are needed to prevent the high-pressure steam unbalancing the trim. If these seals or surfaces become worn or damaged, it can unbalance the trim and stem loads can fluctuate dramatically, causing the valve to oscillate violently or not open on command.

When the DSCV-SA pilot plug is open, high-pressure inlet steam floods the underside of the main plug and the steam atomizing unit operates in preparation of the incoming cooling water from the water control valve. The pilot plug shoulder engages with the underside of the tandem cap of the main plug, which then starts to lift and the main seat opens.

Minimising installation space

As the main plug opens, steam first enters the valve via a heavy duty distribution spacer. The steam passes through the spacer by means of numerous holes evenly positioned around the circumference. This distribution spacer is specifically designed to negate any upstream pipework-induced flow disturbance being communicated to the main plug. This is important because long radius bends or isolation valves can be fitted directly to the valve inlet to minimise installation space. The main plug is fully guided by the cage and spacer to ensure complete plug stability through full travel.

After the inlet steam has passed through the distribution spacer, it then travels through the main seat area to the underside of the main plug via large feed ports. With the main plug lifted, the pressure reducing ports of the cage now open to allow the steam to be pressure reduced in a controlled manner. As the main plug opens further, more pressure reducing ports are exposed and the steam flow rate increases.

Mark Wheat is business unit manager at Celeros Flow Technology

For more information:

Tel: +44 1909 482323

- Safety engineering guide published by Institution of Mechanical Engineers

- The Society of Operations Engineers backs Maintec

- Embrace the crisatunity, business-as-usual is complacency

- Hinojosa improves responsible waste management

- Reducing machine downtime via mixed reality

- Boiler management in the metaverse

- Ceemet and Make UK call on the EU 27 to work with UK to avoid no deal catastrophe

- NPL opens state-of-the-art mechanical test facility

- The patchy case of maintenance in the food & drink industry

- Technology helps Carlsberg through huge automation project