|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Productivity & time gains |

ARTICLE

Productivity & time gains

25 January 2013

A new issue of Dormer's global newsletter - D.World - is now available. In this latest edition, customers discuss how they each overcame machining challenges. Among these, Ortosintese, a Brazilian manufacturer of me

A new issue of Dormer's

global newsletter - D.World -

is now available. In this latest

edition, customers discuss

how they each overcame

machining challenges.

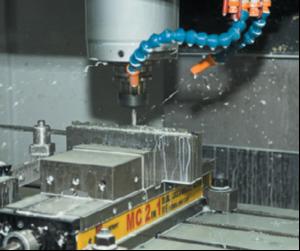

Among these, Ortosintese, a Brazilian manufacturer of medical implants, needed to reduce drilling time involved in the manufacture of an orthopaedic prosthesis. The high tensile strength of the workpiece caused excessive tool wear, meaning the cutting data had to be reduced significantly. Dormer recommended its R567 CDXInox drill - a tool designed specifically for machining stainless steels and exotic alloys. The results speak for themselves: feed rate tripled, time per hole fell by 70% and tool life increased by more than ten-times, resulting in annual tool consumption savings of 68%.

Among these, Ortosintese, a Brazilian manufacturer of medical implants, needed to reduce drilling time involved in the manufacture of an orthopaedic prosthesis. The high tensile strength of the workpiece caused excessive tool wear, meaning the cutting data had to be reduced significantly. Dormer recommended its R567 CDXInox drill - a tool designed specifically for machining stainless steels and exotic alloys. The results speak for themselves: feed rate tripled, time per hole fell by 70% and tool life increased by more than ten-times, resulting in annual tool consumption savings of 68%.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION