|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cables, connectors and energy chains | >Fire-resistant and easy-to-install |

ARTICLE

Fire-resistant and easy-to-install

25 January 2013

An advance in the materials science related to the properties of the cable insulation known as INFIT has made it possible to develop new families of electrical power and data cables with a high level of fire resistance u

An advance in the materials science related to the

properties of the cable insulation known as INFIT has made

it possible to develop new families of electrical power and

data cables with a high level of fire resistance using classical

extrusion methods.Arnaud Piechaczyk, R&D group leader,

Nexans International Research Centre in Lyons explains

During the critical building evacuation and fire fighting periods required by stringent national and international standards, fire-resistant cables play a key role in ensuring the integrity and continuity of vital safety circuits. In many cases, the need for cables to deliver the required levels of performance, reliability and safety has forced designers and installers of electrical systems to compromise on other desirable properties regarding ease of handling and installation.

Until now, the cable industry has mainly relied on two major technologies to ensure the integrity of flexible cable insulation during a fire: XLPE/Mica taping and ceramic forming silicone rubbers. Each of these technologies presents a number of advantages. The classical insulation taping based on Mica, and largely used since the 80s, can easily be implemented on an industrial scale to provide a tough, effective electrical insulation when overlaid with a cross-linked polyethylene (XLPE) coating. It is strong but stiff to handle, so can present some installation difficulties.

On the other hand, silicone rubber insulation can be extruded directly on to the conductors, and offers a good compromise between fire performance and ease of installation thanks to its flexibility. It is, however, vulnerable to cuts and tears.

Increasing customer demands for improved fire performance, together with strippability, ease of installation and connection prompted Nexans to search for a new insulation technology that could offer all these benefits.

INFIT combines, in a polymeric material, the advantages offered by both the tough Mica tapes layer and the extruded silicone insulation layer. This now enables the manufacture of fire-performance cables that are both tough and easy to handle as well as being easy to strip and install.

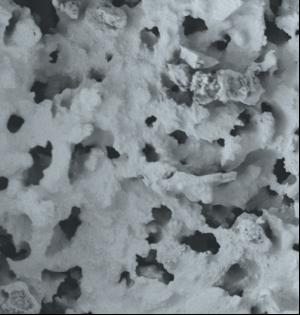

INFIT technology offers enhanced fireperformance because, when the insulation is exposed to fire, it transforms from a flexible, plastic covering to a tough insulating ceramic layer, hardening like clay in a potter's oven to form a protective shield. The key to the success of the new insulation has been in using advanced materials and polymer science to optimise the nanostructure of the primary insulation materials. A combination has been found that reduces the occurrence of cracks or breaks in the insulation to preserve the operational integrity of the circuit, ie preventing short-circuits.

Extensive laboratory tests have shown that cables with INFIT insulation continue to deliver power in the event of a fire, long after the plastic sheath and insulation have burnt away. This means that, for example, exit lighting, smoke and heat exhaust ventilators, fans or pumps will still function reliably, even in areas directly affected by fire, ensuring safe evacuation.

Applications Depending on the specific cable application, the new insulation material can be offered in either a cross-linked or thermoplastic version. This enables cables to offer a combination of fire, mechanical, electrical or thermal properties optimised for each application.

INFIT is a proprietary Nexans technology.

Cables insulated with INFIT can, for example, resist fires reaching temperatures of around 1000°C, at voltages to 1kV, exhibiting a high level of char cohesion and electrical insulation. The product is gradually being deployed across the Nexans fire-resistant ranges. This will include power, communications, control and LAN cables for use in industrial applications and public buildings, and it is expected to be of interest to the marine sector.

During the critical building evacuation and fire fighting periods required by stringent national and international standards, fire-resistant cables play a key role in ensuring the integrity and continuity of vital safety circuits. In many cases, the need for cables to deliver the required levels of performance, reliability and safety has forced designers and installers of electrical systems to compromise on other desirable properties regarding ease of handling and installation.

Until now, the cable industry has mainly relied on two major technologies to ensure the integrity of flexible cable insulation during a fire: XLPE/Mica taping and ceramic forming silicone rubbers. Each of these technologies presents a number of advantages. The classical insulation taping based on Mica, and largely used since the 80s, can easily be implemented on an industrial scale to provide a tough, effective electrical insulation when overlaid with a cross-linked polyethylene (XLPE) coating. It is strong but stiff to handle, so can present some installation difficulties.

On the other hand, silicone rubber insulation can be extruded directly on to the conductors, and offers a good compromise between fire performance and ease of installation thanks to its flexibility. It is, however, vulnerable to cuts and tears.

Increasing customer demands for improved fire performance, together with strippability, ease of installation and connection prompted Nexans to search for a new insulation technology that could offer all these benefits.

INFIT combines, in a polymeric material, the advantages offered by both the tough Mica tapes layer and the extruded silicone insulation layer. This now enables the manufacture of fire-performance cables that are both tough and easy to handle as well as being easy to strip and install.

INFIT technology offers enhanced fireperformance because, when the insulation is exposed to fire, it transforms from a flexible, plastic covering to a tough insulating ceramic layer, hardening like clay in a potter's oven to form a protective shield. The key to the success of the new insulation has been in using advanced materials and polymer science to optimise the nanostructure of the primary insulation materials. A combination has been found that reduces the occurrence of cracks or breaks in the insulation to preserve the operational integrity of the circuit, ie preventing short-circuits.

Extensive laboratory tests have shown that cables with INFIT insulation continue to deliver power in the event of a fire, long after the plastic sheath and insulation have burnt away. This means that, for example, exit lighting, smoke and heat exhaust ventilators, fans or pumps will still function reliably, even in areas directly affected by fire, ensuring safe evacuation.

Applications Depending on the specific cable application, the new insulation material can be offered in either a cross-linked or thermoplastic version. This enables cables to offer a combination of fire, mechanical, electrical or thermal properties optimised for each application.

INFIT is a proprietary Nexans technology.

Cables insulated with INFIT can, for example, resist fires reaching temperatures of around 1000°C, at voltages to 1kV, exhibiting a high level of char cohesion and electrical insulation. The product is gradually being deployed across the Nexans fire-resistant ranges. This will include power, communications, control and LAN cables for use in industrial applications and public buildings, and it is expected to be of interest to the marine sector.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION