|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Deburring equipment | >Finishing touch |

ARTICLE

Finishing touch

25 January 2013

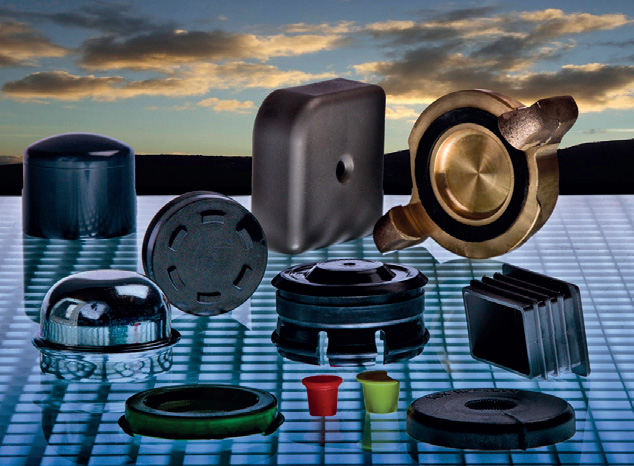

Blue Diamond recognises an increasing demand for custom made ends caps that finish off and add value to a range of products. Not only do they enhance appearance, they can be designed to prevent the ingress of dirt or du

Blue Diamond recognises an

increasing demand for custom made

ends caps that finish off and add

value to a range of products. Not

only do they enhance appearance,

they can be designed to prevent the

ingress of dirt or dust and, in the

case of furniture legs for example,

spread the load alleviating damage to

floor coverings.

Blue Diamond can manufacture end caps in a range of materials including any plastic, rubber, polished metals or alloys to provide a contrasting or a near seamless match to existing finishes. Caps can be threaded or push-fit and, with careful design, it is often possible to produce a universal component that will meet a range of applications - reducing costs and inventory.

Examples include caps and finishers for home and office furniture, access covers, hollow extrusions and piping. Products can be produced in a range of colours to match or tone with the finished item or they can be supplied ready for finishing by the customer. Branding, company logos and identification part numbers can be added and products packaged ready for delivery as required.

Blue Diamond can manufacture end caps in a range of materials including any plastic, rubber, polished metals or alloys to provide a contrasting or a near seamless match to existing finishes. Caps can be threaded or push-fit and, with careful design, it is often possible to produce a universal component that will meet a range of applications - reducing costs and inventory.

Examples include caps and finishers for home and office furniture, access covers, hollow extrusions and piping. Products can be produced in a range of colours to match or tone with the finished item or they can be supplied ready for finishing by the customer. Branding, company logos and identification part numbers can be added and products packaged ready for delivery as required.

MORE FROM THIS COMPANY

- Up close with new microscope video

- 3D scanning technology

- Seal the deal with new design service

- Taking measurement seriously

- Bespoke seals

- Solutions to left- and right- handed dilemma

- Finite element analysis

- Far Eastern manufacturing: Smoothing the journey

- Check out reverse engineering services for non-rectilinear components on Stand No D91

- Custom gaskets

OTHER ARTICLES IN THIS SECTION