|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Boilers and burners | >Quick-to-fit steam traps |

ARTICLE

Quick-to-fit steam traps

25 January 2013

More energy efficient steam systems are the promise of the new STS17.2 steam trapping station launched by Spirax Sarco in an expansion of its Quick-Fit steam trap range. The STS17.2 comprises isolation valves, steam t

More energy efficient steam systems

are the promise of the new STS17.2

steam trapping station launched by

Spirax Sarco in an expansion of its

Quick-Fit steam trap range.

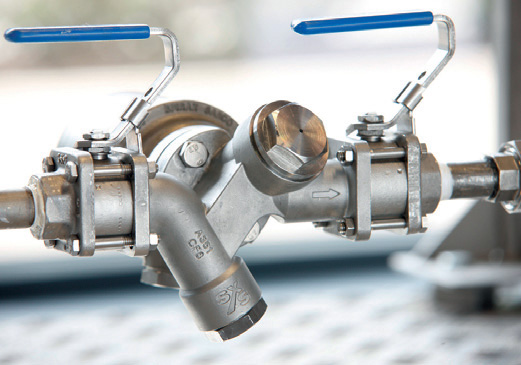

The STS17.2 comprises isolation valves, steam trap connector with strainer and a check valve in a sleek modular body, supported by a 10- year warranty. A steam trap can be replaced in minutes, enabling steam systems to be kept at peak performance and energy efficiency.

Plant downtime is also reduced.

The single-piece body of the STS17.2 virtually eliminates the potential leak paths caused by screwed connections that, says Spirax Sarco, some conventional steam trapping stations and on-site fabricated installations typically suffer.

Paul Mayoh, product manager, says: "The STS17.2's innovative leakfree stainless steel body helps steam system operators to further reduce carbon emissions. Total cost of ownership is lowered through the use of high performance stainless steel components, ensuring long and trouble-free operation." Apart from the steam traps, no other components need be specified or purchased.

A key safety feature is the inclusion of lockable handles on the isolation valves to help ensure maintenance can be carried out safely by minimising the possibility of accidental operation. Internal parts including ball valves, check valve and strainer screen can all be replaced easily.

The STS17.2 comprises isolation valves, steam trap connector with strainer and a check valve in a sleek modular body, supported by a 10- year warranty. A steam trap can be replaced in minutes, enabling steam systems to be kept at peak performance and energy efficiency.

Plant downtime is also reduced.

The single-piece body of the STS17.2 virtually eliminates the potential leak paths caused by screwed connections that, says Spirax Sarco, some conventional steam trapping stations and on-site fabricated installations typically suffer.

Paul Mayoh, product manager, says: "The STS17.2's innovative leakfree stainless steel body helps steam system operators to further reduce carbon emissions. Total cost of ownership is lowered through the use of high performance stainless steel components, ensuring long and trouble-free operation." Apart from the steam traps, no other components need be specified or purchased.

A key safety feature is the inclusion of lockable handles on the isolation valves to help ensure maintenance can be carried out safely by minimising the possibility of accidental operation. Internal parts including ball valves, check valve and strainer screen can all be replaced easily.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION