|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Maintain-in-place |

ARTICLE

Maintain-in-place

25 January 2013

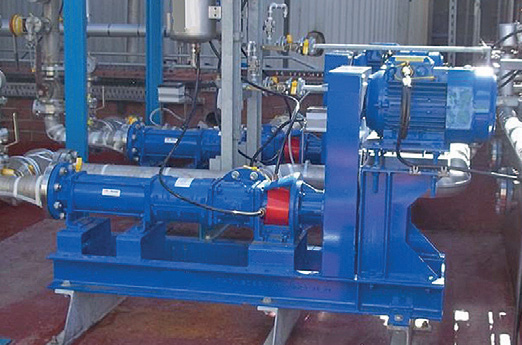

Chemical manufacturer, BASF, has installed four EZstrip maintain-inplace progressing cavity pumps from NOV Mono to transfer a range of varying viscosity products. The company can now strip down and maintain the PC pum

Chemical manufacturer, BASF, has

installed four EZstrip maintain-inplace

progressing cavity pumps from

NOV Mono to transfer a range of

varying viscosity products.

The company can now strip down and maintain the PC pump, in situ and within 30 min, a big reduction in time over the company's previous pumps which has resulted in significant cost savings. The EZstrip pump is an extension of Mono's Compact C range and provides an easy way to disassemble, unblock and maintain a PC pump in-situ.

The company can now strip down and maintain the PC pump, in situ and within 30 min, a big reduction in time over the company's previous pumps which has resulted in significant cost savings. The EZstrip pump is an extension of Mono's Compact C range and provides an easy way to disassemble, unblock and maintain a PC pump in-situ.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION