|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Motors and drives | >Steel maker set to save £68,000 on energy costs |

ARTICLE

Steel maker set to save £68,000 on energy costs

25 January 2013

A specialist steel manufacturer in Rotherham is set to save £68,000 a year on the energy costs of pumping applications following the installation of five ABB industrial drives. The Tata Steel plant produces speciality

A specialist steel manufacturer in

Rotherham is set to save £68,000 a

year on the energy costs of pumping

applications following the installation

of five ABB industrial drives.

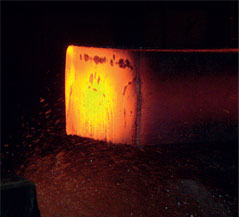

The Tata Steel plant produces speciality steels for customers with demanding applications in aerospace, oil and gas, power generation and the manufacture of industrial bearings.

ABB Drives Alliance member Halcyon Drives supplied, installed and commissioned three, 90kW and two 75kW ABB industrial drives to control critical pumping applications at the plant. Rated at IP55 to stop the ingress of dust and moisture, the drives with in-built intelligent pump function, multi-pump control, ensures that the optimum number of pumps is running to satisfy the process demand and brings a backup pump online in the event of a pump failure.

As part of its energy saving plan, Tata Steel identified its flume flush pumps and filter feed pumps as prime candidates for energy efficiency improvements. During production, hot steel billets are cut by a gas cutter, generating scrap material that flakes off the billet. The three 90kW flume flush pumps are used to flush water across the billet to carry this scrap away. While in production, two flume flush pumps run continuously. This scrap is filtered out of the water, which is then returned to the process via a holding tank, known as a clear well, by two duty 75kW filter feed pumps.

Tata Steel engineers carried out their own investigation, which indicated that controlling the pumps by VSDs would provide significant savings. In particular, the investigation on the filter feed pumps showed that only one pump would be needed to meet the demands of the recirculating water system. One of these pump sets will be removed and used as a spare.

The Tata Steel plant produces speciality steels for customers with demanding applications in aerospace, oil and gas, power generation and the manufacture of industrial bearings.

ABB Drives Alliance member Halcyon Drives supplied, installed and commissioned three, 90kW and two 75kW ABB industrial drives to control critical pumping applications at the plant. Rated at IP55 to stop the ingress of dust and moisture, the drives with in-built intelligent pump function, multi-pump control, ensures that the optimum number of pumps is running to satisfy the process demand and brings a backup pump online in the event of a pump failure.

As part of its energy saving plan, Tata Steel identified its flume flush pumps and filter feed pumps as prime candidates for energy efficiency improvements. During production, hot steel billets are cut by a gas cutter, generating scrap material that flakes off the billet. The three 90kW flume flush pumps are used to flush water across the billet to carry this scrap away. While in production, two flume flush pumps run continuously. This scrap is filtered out of the water, which is then returned to the process via a holding tank, known as a clear well, by two duty 75kW filter feed pumps.

Tata Steel engineers carried out their own investigation, which indicated that controlling the pumps by VSDs would provide significant savings. In particular, the investigation on the filter feed pumps showed that only one pump would be needed to meet the demands of the recirculating water system. One of these pump sets will be removed and used as a spare.

MORE FROM THIS COMPANY

- Control system for power plant

- Productivity increased

- Highly accurate, non-invasive temperature sensor

- Using functional safety in AC drives

- ABB application for pre-emptive maintenance

- Single source benefits

- Variable speed drive eliminates grinder stoppages

- New control system helps cable company cuts costs

- Is it time to replace your VSD?

- Ice pigs in the pipeline

OTHER ARTICLES IN THIS SECTION