|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Boilers and burners | >Recovers flash steam |

Recovers flash steam

29 July 2013

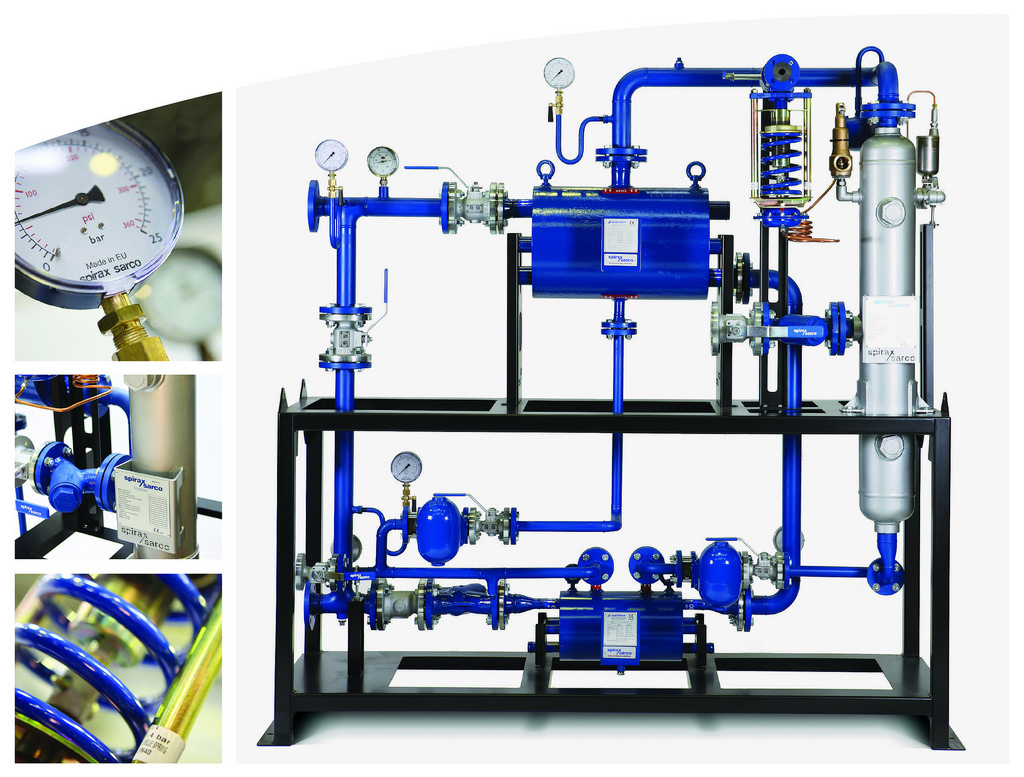

A Spirax Sarco flash steam recovery system is saving Cambridgeshire-based Jardin Corrugated Cases almost £40,000 per year and has reduced the company’s CO2 emissions by 282t per year.

The Spirax Sarco FREME (Flash Recovery Energy Management Equipment) system ensures all the usable heat in the condensate from the steam system can be returned to the boiler. FREME works by passing returning condensate through a heat exchanger system where it heats the boiler feed water. Heating takes place on the high-pressure side of the boiler feed pumps, so the system can safely heat the water to more than 100°C without boiling and causing pump cavitation.

Spirax Sarco also provided automatic boiler blowdown controls with full heat recovery, boiler feedtank insulation and a packaged pump system to ensure all condensate from the main corrugator is returned for recovery.

The entire project has been financed by an interest-free loan through the Carbon Trust – all organised by Spirax Sarco.