|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Upgraded communication |

Upgraded communication

19 September 2013

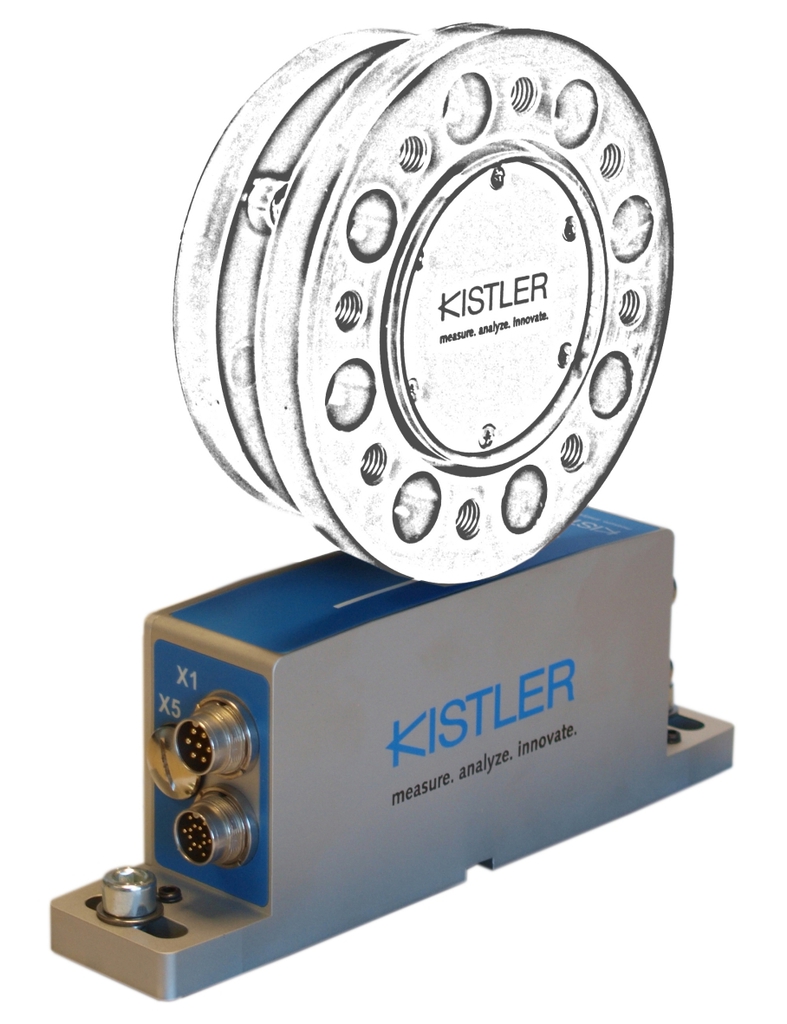

The Kistler KiTorq torque sensor system is now available with Profibus, Profinet CANopen, Ethercat and EthernetIP interfaces in addition to analog/frequency, USB and RS-232 interfaces.

The new stator is fully compatible with all KiTorq type 4550A rotors. The new communication options allow the KiTorq system to be integrated directly into the user’s test environment through the fieldbus interfaces. This saves time during installation and eliminates the cost of additional equipment to convert measured data making the new KiTorq stator highly cost effective for test stand design, installation and operation in applications for electric motor, internal combustion engine, transmissions, pump and compressor testing.

The new stator can be used with any KiTorq rotor of the same speed rating and will automatically recognise the rotor measuring range. With rotors available with seven measuring ranges from 100 to 5000 Nm, hardware investment is minimised as one stator may be used with rotors of differing ranges for different applications. Installation is simplified by the contactless, digital telemetry that eliminates the need for an antenna ring while maintaining the signal bandwidth of 10 kHz and accuracy of better than 0.05% of range. A speed measurement of 60 pulses per revolution is integrated in the standard system.

- Miniature low level force sensor

- Four billion miles of monitoring

- Strain sensors monitor welding

- Electro-mechanical joining modules

- Kistler launches compact joining module

- Pressure sensor validates

- Process monitoring system for those serving the medtech sector

- Kistler launches charge amplifier with IO-Link technology

- Accelerometers

- Force measuring on hand