|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Boilers and burners | >Flash steam recovery trims gas bill |

| Home> | Energy Management | >Boilers and burners | >Flash steam recovery trims gas bill |

Flash steam recovery trims gas bill

17 September 2014

Biomar Grangemouth has sliced between 9 and 10% off its annual gas bill with the help of a system to recover energy from flash steam that would otherwise be lost to atmosphere.

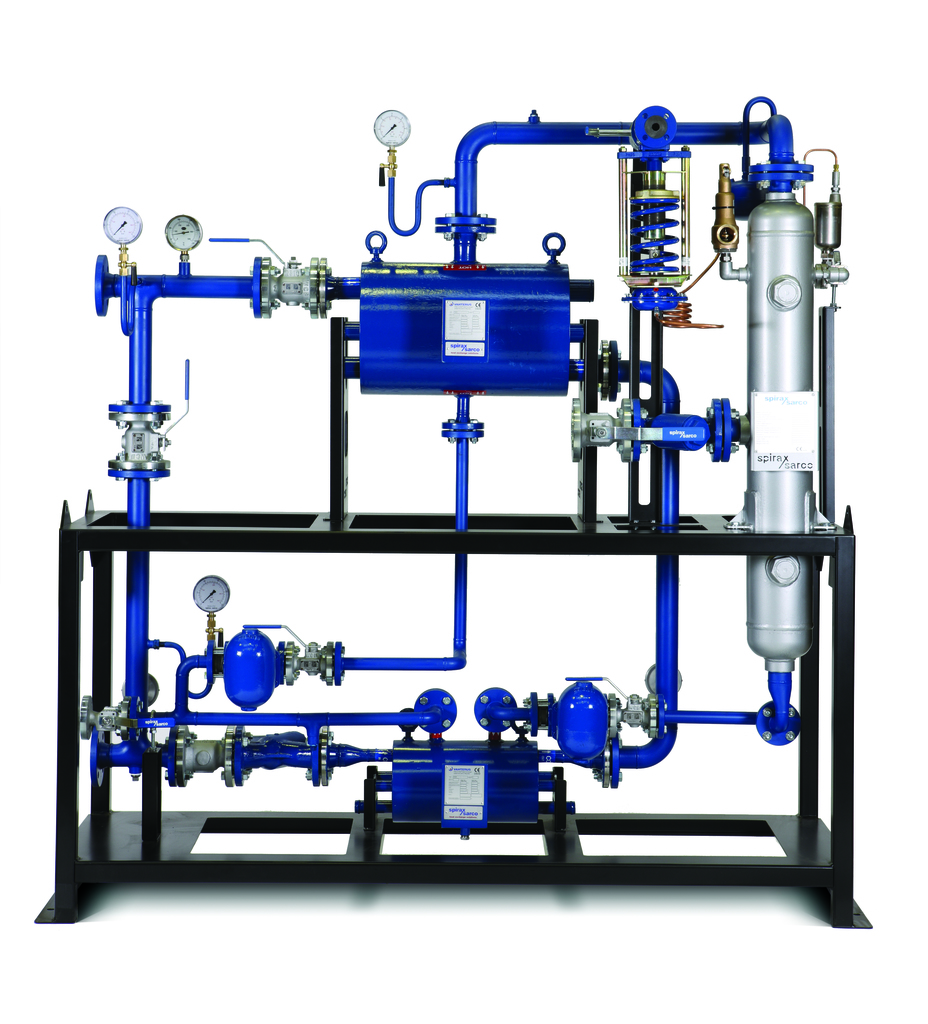

The aquaculture manufacturer says that the energy savings alone mean that the Flash Recovery Energy Management Equipment (FREME) engineered system from Spirax Sarco has paid for itself about 10 times in the four years since installation.

The site uses around 7700kg/h of steam in its production process, with its flat bed dryers alone using between 2500 and 4500kg/h. Before the arrival of the Spirax Sarco system, the flash steam from the returning dryer condensate was vented to atmosphere.

Christopher Strain, engineering manager, says: "Spirax Sarco worked with Biomar to design, build and deliver a complete package flash steam recovery system. Close co-ordination between Spirax Sarco and our team ensured the system was delivered on time, on specification and on budget.”

Condensate and flash steam from the dryers enters a flash recovery vessel, which separates them into two streams. Each stream then flows through its own dedicated plate heat exchanger, which transfers the energy in the flash steam and condensate to the boiler feedwater. The system is positioned on the high-pressure (downstream) side of the feed pump, so it safely raises the temperature of the pressurised feedwater to around 130°C, rather than the 85°C typically achieved under the old regime.

The system was preassembled at Spirax Sarco’s Cheltenham facility and supplied skid-mounted. It was installed and integrated with Biomar’s existing systems during a single, normal maintenance shutdown. "The modular approach was helpful for the installation and the Spirax Sarco team was very supportive,” says Strain.

Biomar has experienced a range of benefits following the installation, including substantial energy and water savings, but there have also been improvements in the stability of the steam system, with less firing up and down in the boiler.

Strain also cites reduced water treatment and boiler maintenance costs. The improved quality of the condensate minimises boiler contamination and corrosion, with a knock-on effect on maintenance costs and downtime. "Overall savings on water treatment fell by almost 40%. We have seen substantial savings in both direct and indirect costs on maintenance time and manpower and increased uptime on boiler performance,” he confirms.

The Spirax Sarco system has also delivered on the other main goal of the project by eliminating unsightly plumes of steam from outside the building.

"Project management was integral to the service provided by Spirax Sarco and our contact Allan Stewart,” says Christopher Strain. "This was delivered in a professional manner and maintained with follow-up site visits to ensure the system was working at its optimum level and that every possible kilowatt of energy was being utilised.”

- Steaming ahead

- Energy-saving steam project

- Touchscreen control doubles energy savings from Spirax EasiHeat on-demand hot water engineered systems

- Gas bills slashed

- Flash steam recovery

- Steam technology centre opens

- BG01 boiler safety guidance: How to comply

- Valves delivered within 48h

- Rental scheme steams ahead

- Recovers energy