|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Increased clamping force |

ARTICLE

Increased clamping force

08 October 2015

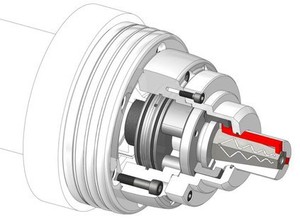

New from Hainbuch, the MAXXOS mandrel system for machining in challenging environments and applications, incorporates the company’s innovative hexagonal clamping geometry.

Using this technology on its mandrel line, Hainbuch can boast clamping force increases beyond 30% when compared to existing systems.

Force is transmitted through positive locking, which results in optimum process reliability and long maintenance intervals. The full-surface contact and the lubrication significantly reduce friction and also enable sensitive clamping for fragile work pieces.

MORE FROM THIS COMPANY

RELATED ARTICLES

OTHER ARTICLES IN THIS SECTION