|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Boilers and burners | >High-temperature, high-pressure conductivity sensor for boilers |

| Home> | Handbooks | >IPE Ireland | >High-temperature, high-pressure conductivity sensor for boilers |

| Home> | Plant, Process & Control | >Sensors and instrumentation | >High-temperature, high-pressure conductivity sensor for boilers |

High-temperature, high-pressure conductivity sensor for boilers

30 June 2016

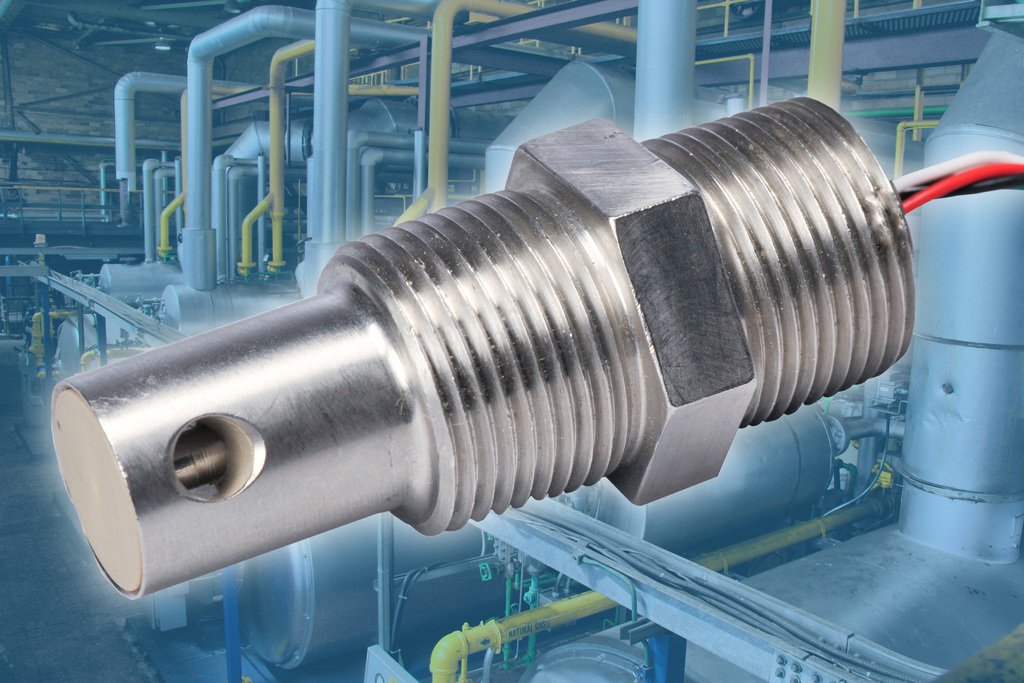

A new in-line high-temperature and high-pressure conductivity sensor from Sensorex has been designed for use in industrial boilers. It provides accurate, repeatable conductivity measurements at saturated steam conditions to 600 psig (41.4 bar) and temperatures to 252°C without cooling the process sample.

The CS875 sensor enables continuous automatic blowdown control, minimising corrosion and scaling. By eliminating excessive blowdown in higher pressure boilers, energy and treatment chemical use can be reduced. The sensor is designed for use with most makes and models of conductivity transmitters or controllers.

Sensors have 3/4in male NPT mounting threads with a 1in insertion depth for easy installation. Both the body and the measuring pin are constructed of 316 stainless steel. A special thermally resistant PEEK insert and high temperature Perfluoroelastomer o-rings ensure reliability at extreme boiler temperatures. Two models are available to suit application requirements – the CS875HT, and the CS875HTTC with ATC temperature element.

All Sensorex probes are supplied with 6in PTFE coated leads as standard for integral mounting to a forged steel junction box/conduit assembly. Longer cable lengths are available at additional cost.