|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Help with tank emptying tasks |

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >Help with tank emptying tasks |

Help with tank emptying tasks

30 March 2017

AxFlow is now offering a compressor system as an alternative to centrifugal pumps for emptying liquefied gas from storage tanks, vessels and mobile tankers.

The compressor system will transfer over 99% of the liquefied gas, thereby enabling users to recover this potentially expensive liquid heel. The system also eliminates the problem of liquefied gases boiling when centrifugal pumps are used.

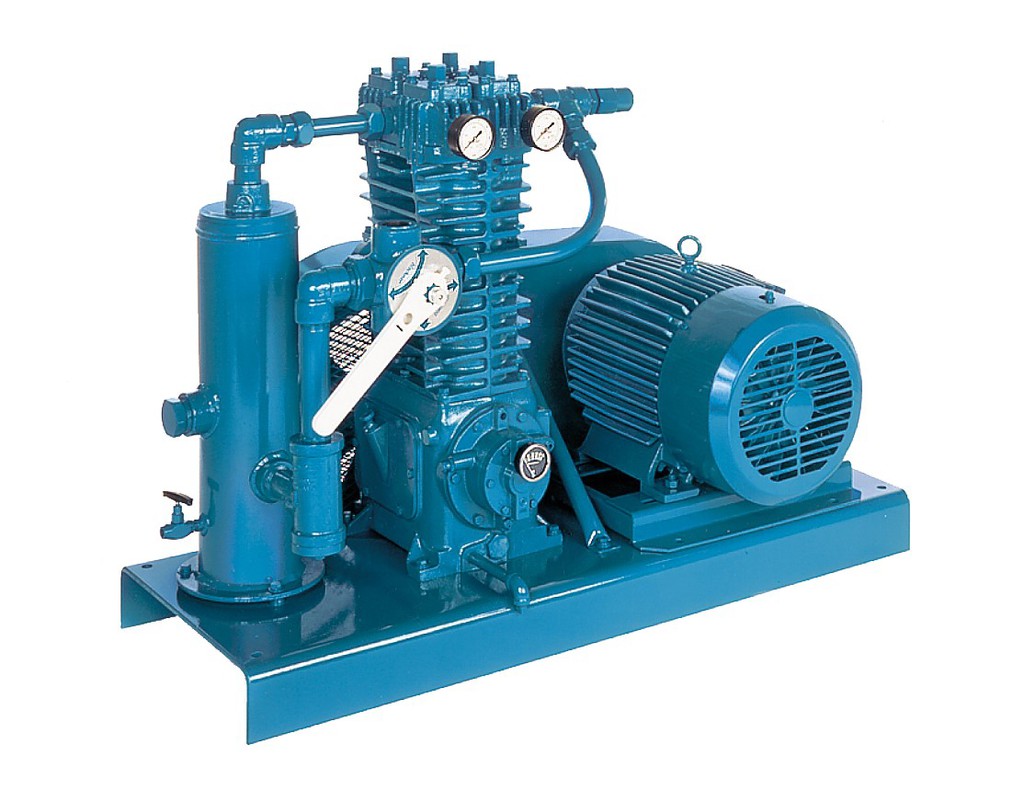

AxFlow’s VRS is a simple frame-mounted unit which can be used for intermittent and continuous duties. Available in mobile and static formats, the VRS is divided into two stages, liquid transfer and vapour recovery. The function of the compressor is to push the liquid from inside the tanker into the storage vessel using pressurised vapour from the storage vessel. Following this, the compressor connections are reversed using a 4-way valve to suck out any remaining vapour in the tanker and transfer it to the storage vessel.

Designed specifically for liquefied gas transfer duties, the vertical piston compressor comes in single or two stage versions with air or water-cooling. Engineered to meet customer’s specific requirements, the VRS enables liquid transfer or gas evacuation down to pressures of 50 millibar absolute, and is suitable for displacements of up to 212 m3/h and system pressures to 42 bar.