|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Robotics & Automation | >3D simulation program for robot control |

3D simulation program for robot control

07 March 2018

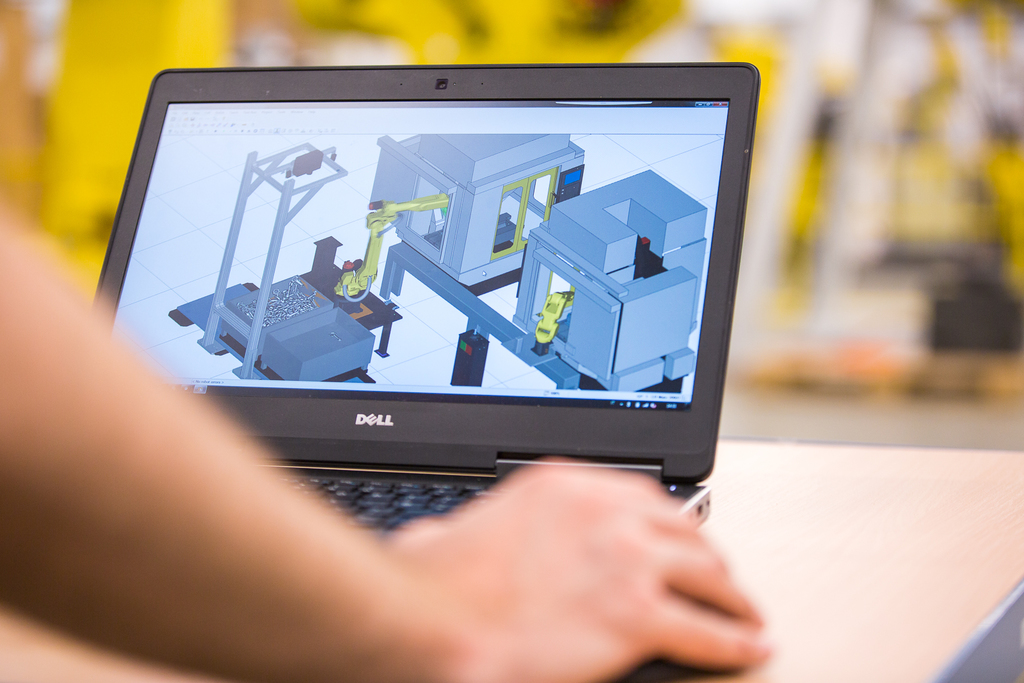

FANUC UK has launched an upgraded version of its intelligent 3D simulation software for robot motion control.

ROBOGUIDE Version 9 can be used for pre-sale concept simulations, through to a full offline programming package for use on the shop floor. It is suitable for both new and experienced robot users, and has several advanced features, including a more intuitive user interface, up-to-date virtual controllers, and a drag-and-drop function for the addition of robots and components within a work cell layout.

The ROBOGUIDE software can also support FANUC’s latest R30iB Plus robot controller, which includes the new iHMI interface that is common across the entire product range.

FANUC’s ROBOGUIDE software allows operators to design, test and modify robotic systems through the use of a fully-simulated, 3D, CAD environment. The simulations, which can be conducted offline, provide an operator with accurate robot motion and cycle times when designing and verifying a system. The finalised program can then be downloaded to the robot.

Additional plug-ins are available for the calculation of reducer lifetimes, motor duties and power consumption, while plug-ins monitoring possible collisions and enforced safety parameters, particularly for collaborative robots, come as standard.

The software is designed to be as intuitive as possible, allowing 3D CAD to be imported directly into a cell layout. The software also includes a KAREL editor and compiler for advanced customisation and programming.

Industry-specific versions of ROBOGUIDE are available, including: ChamferingPro for deburring, HandlingPRO for material handling processes, PAINTPRO for paint applications (an additional spray simulation plug-in is available to aid process development), and WeldPRO for arc-welding applications. CAD-to-path functionality, which automatically generates programs based on CAD data, is available as standard in all versions of ROBOGUIDE.

For enhanced capabilities in robot cells, users of the latest version of ROBOGUIDE can benefit from additional smart FANUC software, includingiRVision and line-tracking.

- From drill and tap to complete job

- FANUC ROBOCUT production hits 30000 units

- FANUC extends handling robot range

- Robot's role

- Collaborative robot

- Increased capacity and space savings

- FANUC cobot eases pain for Takeda Pharmaceutical

- Medium-sized 'cobot' introduced

- Latest robots: Slim and easy to install

- High-speed, high-precision processing fibre lasers

- Latest robots: Slim and easy to install

- APP that controls robots

- Collaborative robots: Risks and rewards

- Precision bearings aid smart grasping

- Collaborative robots: Safety matters

- Bearings chosen for robotic exoskeletons

- Cobot collaboration delivers entry-level vision-guidance

- Robots boost profitability for machining company

- Entry-level vision-guided cobot system

- Fully automatic split case picking