|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Electrical components | >Into the danger zone: The role of cable glands in explosive atmospheres |

Into the danger zone: The role of cable glands in explosive atmospheres

17 December 2025

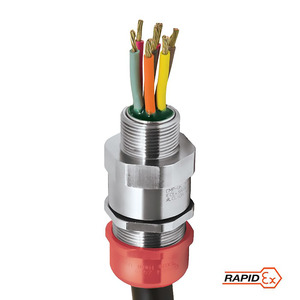

Cable glands may look unassuming but they play a vital role in an electrical installation's functionality, safety and performance - whether it be in a large data centre, a wind turbine or a petrochemical plant with a potentially explosive atmosphere, explains Lee Frizzell

CABLE GLANDS are unobtrusive products; so much so that asking a layperson to locate them in an electrical installation and explain their purpose would most likely lead to a blank stare.

What are they and what do they do?

In a nutshell, cable glands are mechanical cable entry devices that are used throughout all industries in conjunction with cable and wiring used in the electrical, instrumentation, control and automation systems.

They provide environmental protection, facilitate earth continuity, are able to withstand a short circuit fault current, and they maintain a restraining force on the cable to prevent slippage, which ultimately prevents cable pull loads being applied to the cable conductor terminations inside the enclosure.

Special considerations in explosive atmospheres

Cable glands used in explosive atmospheres can differ significantly from cable glands manufactured for normal industrial use, and it’s easy to understand why when you consider the way explosive atmospheres are categorised, defined and governed by industry regulations.

Cable glands are typically installed in Zone 1 or Zone 2. Zone 1 is where an explosive gas atmosphere is likely to occur in normal operation occasionally (e.g. 10 to 1,000 hours per year). Examples: Around the openings of storage tanks, near process pipework, filling or emptying points. Zone 2 is where an explosive gas atmosphere is not likely to exist under normal operating conditions, but if it does it will exist only for a short period of time (e.g. less than 10 hours per year).

There’s then Equipment Protection Levels (EPL Code), which classifies equipment according to the level of protection it provides against ignition. The EPL clarifies the suitability of equipment for use in Zones 0, 1, and 2 (and their dust equivalents). Finally, there’s IEC 60079-14, which sets out the rules for installers of cable glands in explosive atmospheres.

Certification and compliance requirements

When used in explosive atmospheres, it’s crucial that cable glands are appropriately certified and selected correctly according to the specified installation code or standard requirements, taking into account any certification limitations or conditions of use. They must also be approved for the type of cable selected and be suitable for the specific application, expected ambient temperatures, local climate, environmental exposure and any other adverse conditions.

The easiest, fastest and most cost-effective way of ensuring the safety of electrical equipment is to use high quality cable glands from manufacturers whose products are tried, tested and trusted in all environments.

Electrical installations are vital wherever they’re found; operating equipment is costly; and installation is time-consuming and can only be carried out by experts. Take all that into account and then consider that an electrical installation failure can impact people, businesses and property; it’s clear that there’s no room for error, especially in explosive atmospheres. Therefore, put your trust in the experts and don’t leave anything to chance.

Lee Frizzell is technical director of CMP Products

For more information:

Tel: 0191 743 0411