|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >HPC presents N2 Skid at PPMA |

HPC presents N2 Skid at PPMA

29 July 2025

VISITORS TO HPC Compressed Air Systems' stand at the PPMA Show will be able to see its new Nitrogen Gas (N2) Skid, which HPC is offering on a "try before you buy basis".

HPC’s N2 Skid is a plug and play solution for small to mid-sized enterprises (SMEs) in the food and beverage (F&B) industry.

F&B manufacturers rely on N₂ to keep their products fresh and free from contamination.

If they are SME businesses in the F&B industry, it is vital they find a reliable, consistent supply of N₂, which doesn't break the bank.

HPC’s N2 Skid enables SME F&B manufacturers to generate their own N2 on site, eliminating the need for costly and logistically challenging liquid or gas cylinder deliveries.

As a result, customers can benefit from cost savings of up to 90% by generating their own N2, compared to importing in high pressure cylinders.

An integrated Nitrogen Generation solution, HPC’s N2 Skid incorporates:

- Refrigeration Air Dryer

- Pre-Filtration Package

- Oil Vapour Reduction Filter (to Class 1)

- N₂ Generator

- Buffer Vessel

- Sterile Process Filter

Reliable. Efficient. Pure

HPC’s N2 Skid delivers a continuous, reliable supply of N₂ tailored to the customer’s needs, preventing production time.

It delivers N₂ with ultra-low 0.5% Oxygen (O₂) content, ensuring F&B products maintain their freshness and quality.

Featuring an advanced filtration system, it ensures gas purity by removing impurities and delivering N₂ at the desired O₂ content.

A user-friendly interface allows real-time monitoring of gas output and purity.

With its compact design, it is suitable for all size of operations, but it is equally scalable. Its modular system means it can easily grow as your productions needs do.

N₂ quality is third party validated and certified to European EIGA statute 231/2012 for gas used as a food additive, E941, as well as FDA and Pharmacopoeia compliant.

Nitrogen usage in F&B applications

N2 is an inert gas that preserves product freshness, impedes microbial growth, prevents oxidation, and enhances product quality.

It is widely used in F&B applications, from product blanketing, purging, displacement, Modified Atmosphere Packaging (MAP), or bottling.

Typical sectors in which N2 is used are dairy, snack foods, salads, breweries, wineries, and many others.

Save costs by generating N2 on-site

N2 can easily be produced from a compressed air source. Compressed air is treated and O2 removed to produce the N2 quality that is suitable for any application, at a fraction of the cost of traditional methods of supply.

Cost savings compared to high pressure cylinders are typically around 90%, whereas savings against bulk liquid can range between 60% and 70%.

Payback on investment can often be as little as 12-18 months.

Benefits of HPC’s N2 Skid

- Fully packaged, compact system - plug and play

- Custom solutions available from 2 to 1000 m3/h

- Fully compliant with EU statute 231/2012 for gas used as a food additive (E941)

- N2 on demand as and when you need it at the purity you require

- Low unit gas costs (typically ̴ 10p/m3), saving up to 90% versus traditional methods of supply

- Carbon footprint reduction

- Typical ROI: 2-3 years

- No cylinder changeover / manual handling

- No running out of gas

- No gas wastage or boil-off

- No expensive logistics, deliveries, environmental surcharges

- No on-site delivery trucks, cutting site CO2 emissions

- No specialist H&S training for staff

HPC is offering a trial of its N2 Skid, to enable customers to see how HPC’s packaged solution can benefit their business, before taking the decision to purchase.

For more information, please contact Jamie Crawt, HPC’s National and Specialist Account Manager via 07775 937795 or [email protected]

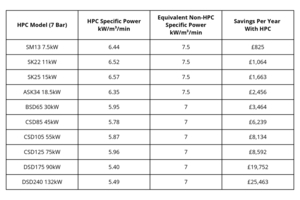

- Energy savings

- Compact dryers

- HPC KAESER: Built to last the distance

- Compact and ultra-efficient

- Efficient motors for air power

- Rotary blower packages

- Saving energy and reducing costs with HPC

- New generation of rotary screw compressors

- Efficient filtration

- Towable compressors are compact, powerful and energy efficient

- MAT - Modular Air Trolley

- Belt drive compressors

- Monitors compressors

- Plugging the skills gap

- Compressor range

- Modular dryer design

- Accurate diagnosis

- Plant complies with latest medical standards

- Hertz Kompressoren UK launches HSC D direct drive air compressor range

- Filter elements tested to ensure air quality