|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >Filter elements tested to ensure air quality |

Filter elements tested to ensure air quality

02 July 2013

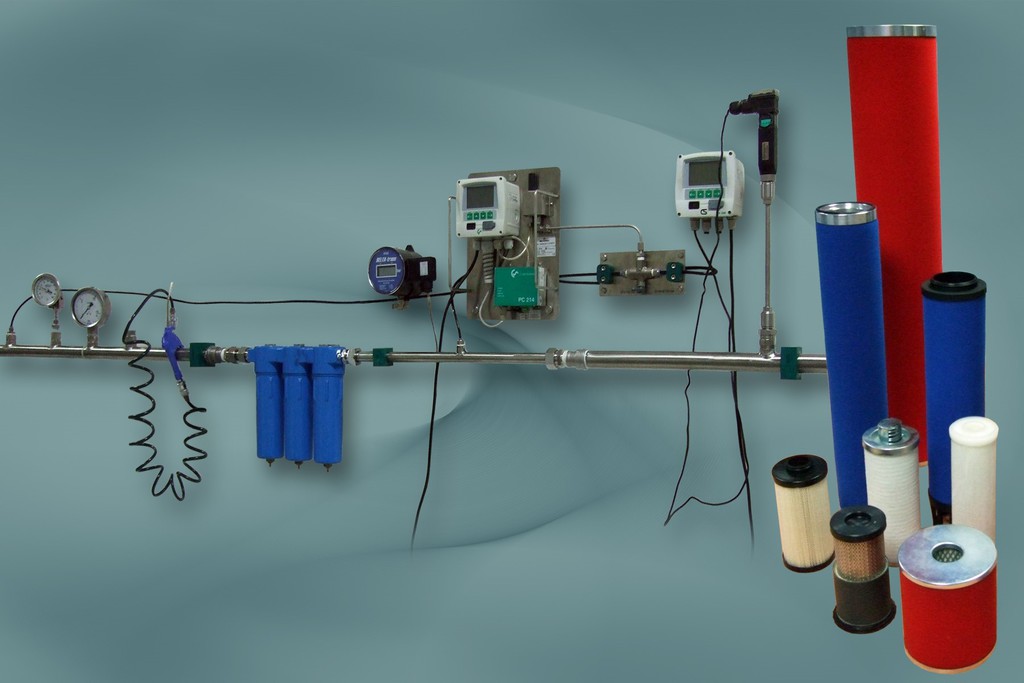

As a key supplier of compressed-air filter elements to the UK market, Hi-line Industries undertake full test and air quality analysis of the filter media that they supply.

Now, however, this valuable service is also available to cover the testing of any filtration media products, including competitors equipment. The choice of the correct filter element has a direct effect on operational costs, and experience shows that the air quality can help minimise or even eliminate unnecessary costs.

Following their investments in state-of-the-art testing equipment including particle counters, flow meters, mass flow controllers and dewpoint meters, Hi-line provide a test facility to measure the efficiency of filter elements. Tests indicate compliance with ISO 8573-1:2010, being the international standard for compressed air quality.

This standard lays down minimum air quality standards and defines allowable content levels for dirt, water and oil. During the compression cycle, any inherent air particulates (dust, pollen, water etc) are drawn into the compressor and entrained into the compressed air stream which typically can be at seven times normal atmospheric conditions. Added to this stream is the carbon, oil and metallic debris from the compression process, generating a potentially toxic and destructive cocktail within the compressed air stream. Even for general factory applications, such contaminated air supplies are not acceptable.

- MAT - Modular Air Trolley

- Belt drive compressors

- Monitors compressors

- Plugging the skills gap

- Compressor range

- Modular dryer design

- Accurate diagnosis

- Plant complies with latest medical standards

- Hertz Kompressoren UK launches HSC D direct drive air compressor range

- Rotary-vane compressors turn up the heat