|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Boilers & burners | >High efficiency low NOx steel shell boilers |

| Home> | Plant, Process & Control | >Boilers and burners | >High efficiency low NOx steel shell boilers |

| Home> | Energy Management | >Boilers and burners | >High efficiency low NOx steel shell boilers |

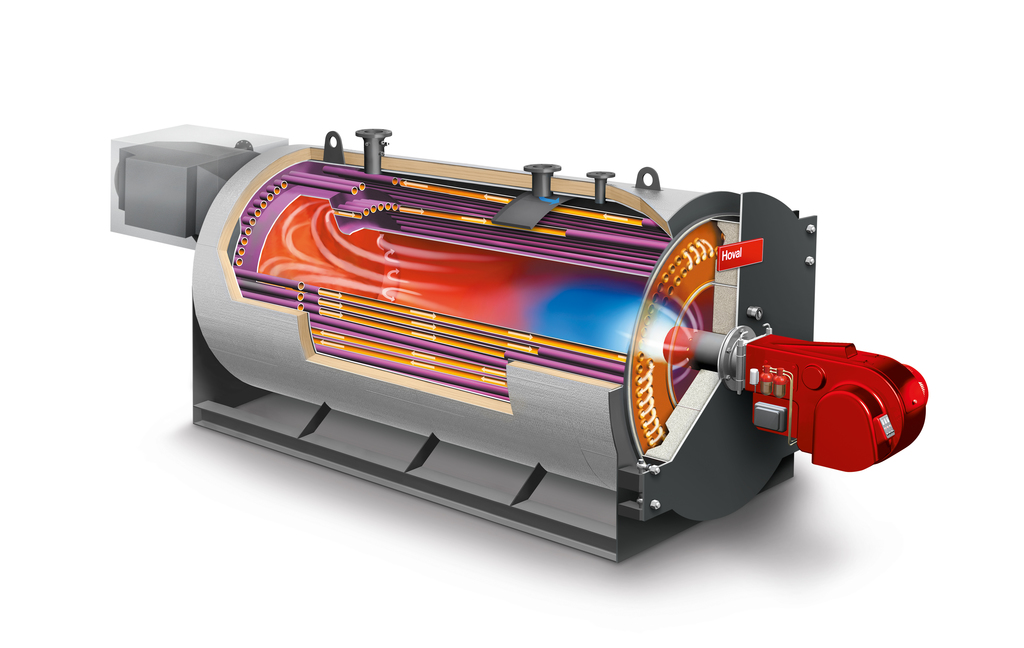

High efficiency low NOx steel shell boilers

30 January 2019

Hoval's range of high efficiency, low NOx steel shell boilers now includes the Max-3 E and Max-3 condens E. These come in four sizes in outputs to 6800kW in gas and dual fuel options.

Key features include return inlets with injection effect to ensure return water is heated evenly – avoiding condensation on the flue surface and extending service life.

A low NOx burner is supplied as standard in both models to ensure compliance with the Medium Combustion Plant Directive (MCPD). This is combined with three-pass technology in the Hoval Max-3 E to reduce emissions even further, with retarders in the third pass tubes to improve heat transfer and efficiency.

The Hoval Max-3 condens E also uses a three-pass heat exchanger design, combined with an integrated flue gas condensing heat exchanger with a large heat transfer surface to increase the rate of condensation. Hoval says the large tube diameter of the gas heat exchanger reduces hydraulic resistance so that a smaller pump can be used (compared to boilers with a narrower tube).

Both boiler models are delivered assembled and ready to use, complete with full thermal insulation and aluminium cladding, as well as flexibly adjustable connections for ease of installation. The large, thermally-insulated boiler door ensures easy access for cleaning and maintenance, and the tube nest area of the second pass can also be easily accessed thanks to the large combustion and reversal chambers.