|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Lubricants | >Condition-based lubrication: Reducing premature bearing failures with ultrasound |

Condition-based lubrication: Reducing premature bearing failures with ultrasound

25 July 2024

Ahead of the company's presentation at the Industrial Maintenance Solutions Summit, UE Systems' Christopher Hallum discusses the role ultrasound can play in helping improve your lubrication practices

BEARING LUBRICATION is possibly one of the most important tasks for any maintenance and reliability team. And yet, we still see many industrial facilities many having poor lubrication practices, leading to premature bearing failure.

The most common issue is maintenance departments carrying a time-based lubrication strategy (or sometimes no strategy at all!) - eventually, this approach will lead to both under- and over-lubrication issues. A much better approach is to lubricate not based on time, but on the bearings’ condition.

It has been estimated that 60-90% of all bearing failures are lubrication related. Bearing failures most often lead to unplanned downtime which can impact production as well as affect all related components around the bearing. Downtime is costly. Since the most common cause of bearing failure is lubrication related, it’s clear to see that lubrication is serious business. And for the longest time, that 'serious business' has been conducted in a way that on its face makes perfect sense - but in fact borders on haphazard.

Time-based lubrication leads to over-lubrication

Many technicians, unfortunately, have relied on preventive, time-based lubrication alone. That is, every X number of months, the grease gun comes out, and the bearings are lubricated. But by relying solely on time-based lubrication, or even a combination of planned maintenance and temperature readings to serve as a proxy for lubrication status, one runs the risk of something just as bad, if not worse: over-lubrication. In fact over-lubrication has been reported both anecdotally and in presentations at various conferences to be the primary cause of premature bearing failure.

Relying on time-based, periodic lubrication assumes bearings need to be greased at defined time periods. Often this evolves into a well-intentioned guessing game at best. Adding more lubrication to a bearing that is already adequately greased is a real risk.

How ultrasound improves lubrication practices

Ultrasonic equipment detects airborne and structure borne ultrasounds normally inaudible to the human ear and electronically transposes them into audible signals that a tech can hear through headphones and view on a display panel as decibel (dB) levels. With this information, a trained technician can interpret the bearing condition in order to determine what, if any, corrective action is needed.

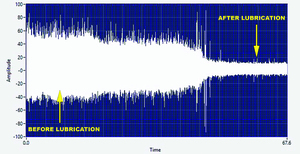

The image in the graph is a Time Wave Form of a recorded ultrasound of a bearing in the process of being lubricated. The approximately one-minute sound file shows the bearing before and after lubrication. Notice the obvious reduction of ultrasound noise on the sound spectrum - this would also be clearly noticed by the inspector when listening to the bearing via the headphones. The sound would get smoother as the bearing is being lubricated.

The bearing dB and amplitude increase as more grease is added, reaching the threshold of over lubrication. This can be avoided by listening to the bearing with an ultrasonic instrument, or keeping an eye on dB levels.

How to get started

1. Select your ultrasound instrument

The first step is to use a proper ultrasound instrument. There are instruments especially designed for bearing lubrication and that can even be attached to a grease gun.

2. Establish baselines

Then, it is necessary to establish a baseline decibel level and get a sound sample. This is ideally done when moving through a route for the first time by first comparing dB levels and sound qualities of similar bearings. Anomalies will be easily identified.

3. Trend your bearings

Once established, each bearing can be trended over time for any changes in either amplitude or sound quality. Generally speaking, when the amplitude of a bearing exceeds 8 dB and there is no difference in the sound quality established at baseline, the bearing needs to be lubricated. To prevent potentially disastrous over-lubrication, the technician will then apply lubrication, a little at a time, until the dB level drops.

4. Collect data

To improve efficiency, it is a good practice for the technician to note when the equipment was last greased and how much grease was used to calculate roughly how much lubrication is used per week. By using ultrasound to lubricate each and every time, the technician produces a historical data that can be used as a guide from previous calculations, helping the department to determine whether the lubrication schedule can be modified, perhaps saving man-hours, and whether the manufacturer’s suggested lubrication amount is accurate (if less is needed, there’s cost-savings potential).

If you want to improve your lubrication practices, join us at IMSS and make sure you don’t miss Christopher Hallum's presentation on how to drastically reduce bearing failures by making some simple adjustments and deploying Ultrasound on your greasing routes.

Christopher Hallum is operations manager - North Europe at UE Systems

For more information:

Tel: +44 (0) 7930 352 188

- Combining sustainability with lifting power: Sarens introduces new SGC-170

- Latest technologies on show

- Haworth Tompkins completes Industria vertical industrial building

- €4m project under way to train next generation of 5G experts

- All round measurement solution

- £20m Government boost for training

- And finally... it's only up for a fracking Oscar!

- Industry lows & highs

- How AI can tackle the engineering skills gap

- MARCH awarded place on £50m United Utilities Monitoring and Control Systems Integration framework

- Distribution

- Lubricants: Sampling, analysis and testing

- Gear lubricant based on water and synthetic base oil

- Oil consumption cut by 6000 to 7000 litres per year.

- Monitor for power transformers

- Lubricant support from online chat robot

- Lubricants, coolants and oil analysis

- Remote monitor for automatic lubrication systems

- Oil consumption cut

- Perils of improper lubrication