|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Joining metals with ultrasonics |

ARTICLE

Joining metals with ultrasonics

25 January 2013

Already a widely used process for joining plastics, ultrasonics is now being used for an increasing number of metal welding applications. Here, Martin Frost, sales manager of Telsonics UK outlines the benefits of the ultr

Already a widely used process for joining plastics,

ultrasonics is now being used for an increasing number of

metal welding applications. Here, Martin Frost, sales

manager of Telsonics UK outlines the benefits of the

ultrasonic welding process

Ultrasonic metal welding is a friction welding process, where oxides and other contaminations present on the material surfaces are broken up and the parts to be welded are brought together under simultaneous pressure. Molecular bonding, similar to the conventional cold-press welding, then takes place. The process also provides optimum strength since no microstructural changes occur in the boundary layer. The joint produced using ultrasonics also provides good resistance and heat rise properties.

Welding metals using ultrasonics differs from the more common plastics welding techniques in that the ultrasonic energy is delivered transversely rather than longitudinally. Telsonic's SoniqTwist concept, for example, is a torsional welding system using circumferential amplitudes. It is also effective for metal welding. Another major difference between plastic and metal welding is that for metals, the joining process takes place at temperatures that are approximately 30 to 40% below the melting temperature of the base material.

Ultrasonics can be used to weld a comprehensive range of thin section, ductile, conductive metals including: copper, nickel, aluminium, brass, silver and gold. This range of metals is commonly found within the electrical, electronics and photovoltaic industries and it is in these sectors where ultrasonic metal welding is becoming more widely used.

Just a few examples of where the technology is already being successfully applied include welding aluminium and copper foils on to connector bars for lithiumion batteries, hermetically sealing aluminium and gold tubes, welding copper leads on to a coated ceramic substrate and wire splicing applications using Telsonic's special purpose Windows-driven splicing machines for wire harness and loom production.

Examples of continuous ultrasonic welding include seam welding composite aluminium and plastic tubes and copper flutes to tubes in the heating and solar panel industries. The capability to join materials with dissimilar properties, very short welding times, low heat generation at the welding point and the resultant weld strength close to that of the base material are all key attributes of the process.

Applying the technology Although the fundamental elements of ultrasonic welding systems for metal share much of the same technology as their plastic welding cousins, Telsonic has developed a range of ultrasonic modules and machines that are configured specifically for metal welding applications. These include linear and torsional welding systems, rotary heads for continuous welding and splice welding systems.

Depending upon the materials to be processed and the welding action to be used, linear, torsional or continuous, ultrasonic modules and machines with frequencies of 20 or 35kHz and with available power from 500W to 10kW can be selected from Telsonic's range. Surface areas of up to 200mm2 can be processed with a weld force of up to 9000N, further expanding the range of ultrasonic metal welding applications.

One of the major benefits of the ultrasonic welding process is the precise control which can be achieved during the welding cycle and the capability to record, store and analyse the weld parameters for quality control purposes.

A number of software extensions are available to work in conjunction with the various metal welding systems. The TelsoResult software package, for example, is suitable for quality control purposes. This version of the software can record data from multiple devices and provides the capability to import statistical data into a spreadsheet format for detailed analysis. TelsoResult is also compatible with PLCs making it suitable for automated manufacturing facilities.

Ultrasonic metal welding is a friction welding process, where oxides and other contaminations present on the material surfaces are broken up and the parts to be welded are brought together under simultaneous pressure. Molecular bonding, similar to the conventional cold-press welding, then takes place. The process also provides optimum strength since no microstructural changes occur in the boundary layer. The joint produced using ultrasonics also provides good resistance and heat rise properties.

Welding metals using ultrasonics differs from the more common plastics welding techniques in that the ultrasonic energy is delivered transversely rather than longitudinally. Telsonic's SoniqTwist concept, for example, is a torsional welding system using circumferential amplitudes. It is also effective for metal welding. Another major difference between plastic and metal welding is that for metals, the joining process takes place at temperatures that are approximately 30 to 40% below the melting temperature of the base material.

Ultrasonics can be used to weld a comprehensive range of thin section, ductile, conductive metals including: copper, nickel, aluminium, brass, silver and gold. This range of metals is commonly found within the electrical, electronics and photovoltaic industries and it is in these sectors where ultrasonic metal welding is becoming more widely used.

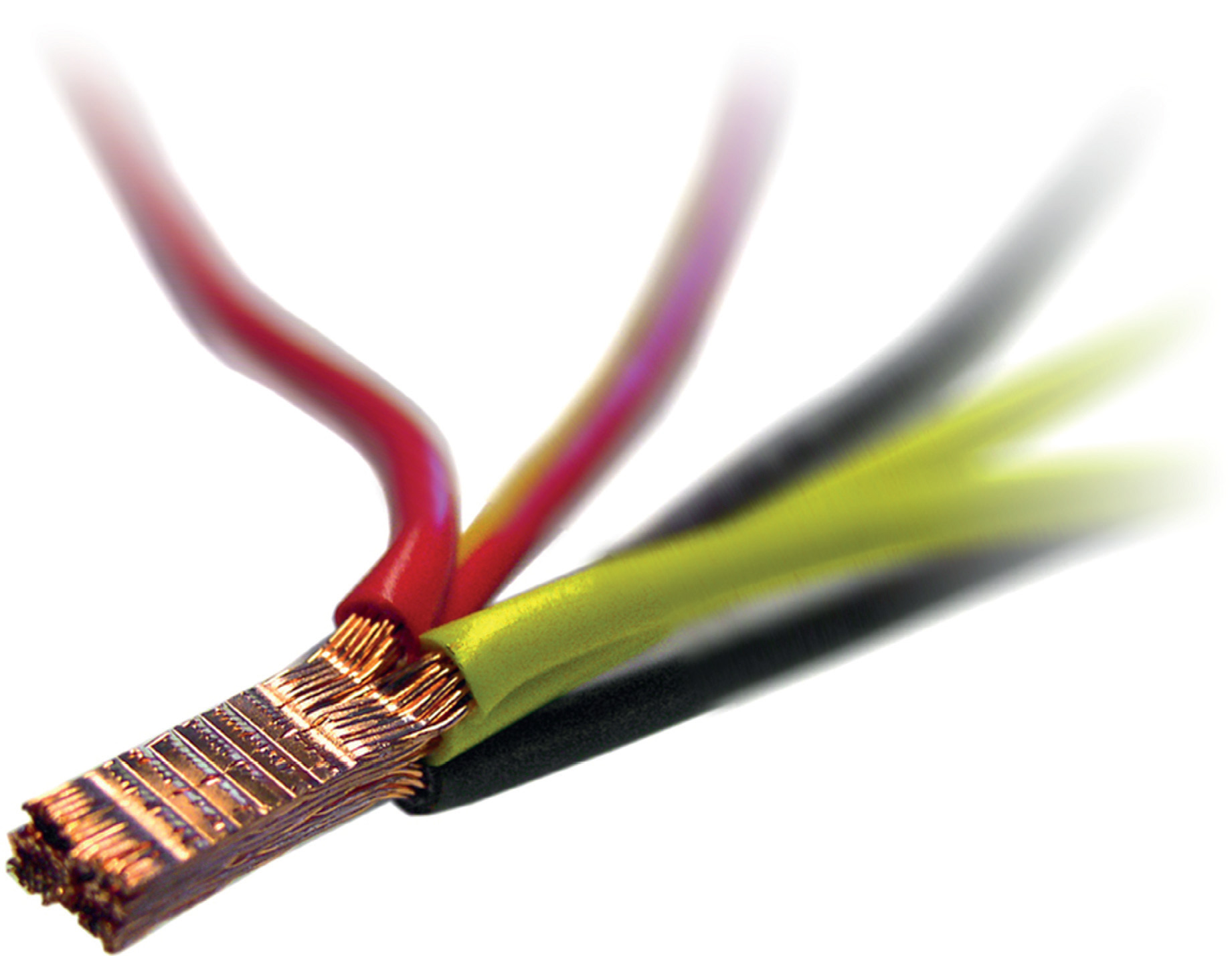

Just a few examples of where the technology is already being successfully applied include welding aluminium and copper foils on to connector bars for lithiumion batteries, hermetically sealing aluminium and gold tubes, welding copper leads on to a coated ceramic substrate and wire splicing applications using Telsonic's special purpose Windows-driven splicing machines for wire harness and loom production.

Examples of continuous ultrasonic welding include seam welding composite aluminium and plastic tubes and copper flutes to tubes in the heating and solar panel industries. The capability to join materials with dissimilar properties, very short welding times, low heat generation at the welding point and the resultant weld strength close to that of the base material are all key attributes of the process.

Applying the technology Although the fundamental elements of ultrasonic welding systems for metal share much of the same technology as their plastic welding cousins, Telsonic has developed a range of ultrasonic modules and machines that are configured specifically for metal welding applications. These include linear and torsional welding systems, rotary heads for continuous welding and splice welding systems.

Depending upon the materials to be processed and the welding action to be used, linear, torsional or continuous, ultrasonic modules and machines with frequencies of 20 or 35kHz and with available power from 500W to 10kW can be selected from Telsonic's range. Surface areas of up to 200mm2 can be processed with a weld force of up to 9000N, further expanding the range of ultrasonic metal welding applications.

One of the major benefits of the ultrasonic welding process is the precise control which can be achieved during the welding cycle and the capability to record, store and analyse the weld parameters for quality control purposes.

A number of software extensions are available to work in conjunction with the various metal welding systems. The TelsoResult software package, for example, is suitable for quality control purposes. This version of the software can record data from multiple devices and provides the capability to import statistical data into a spreadsheet format for detailed analysis. TelsoResult is also compatible with PLCs making it suitable for automated manufacturing facilities.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION