|

Edward Lowton

Editor |

|

ARTICLE

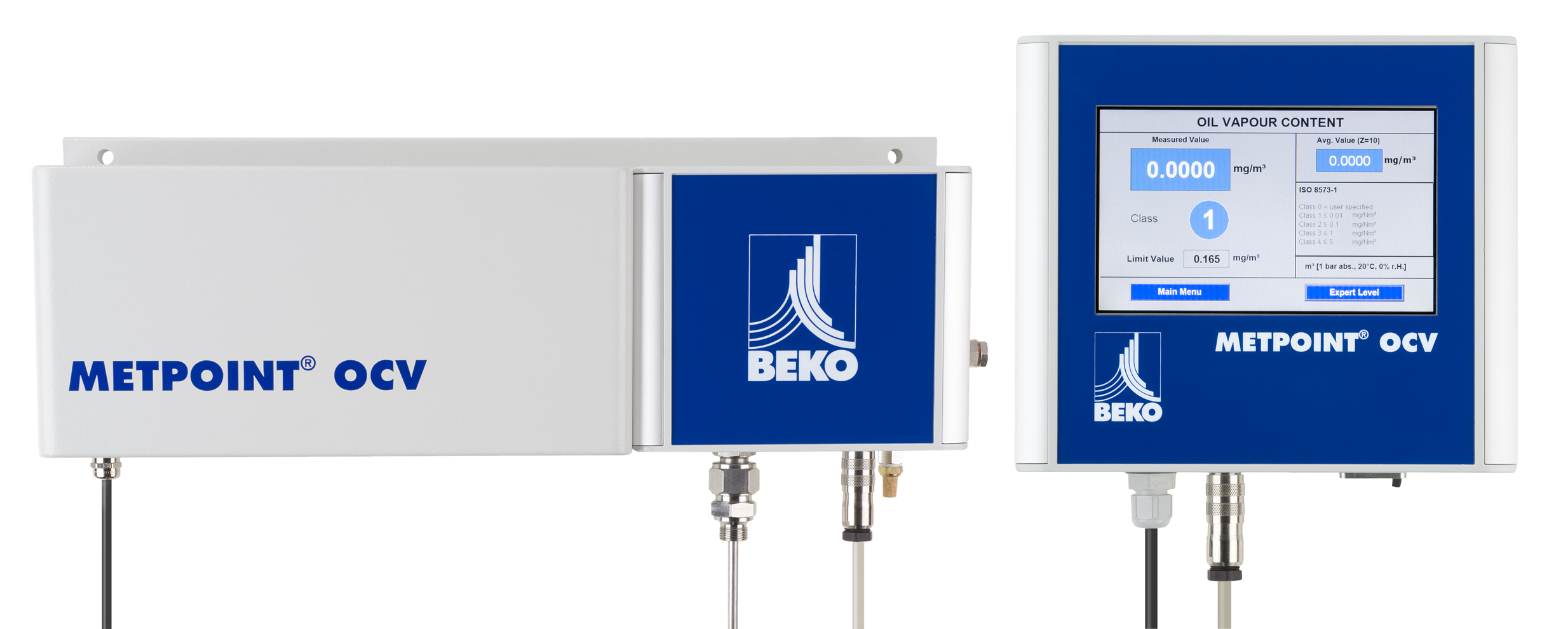

Beko Metpoint OCV

15 May 2014

Measurably constant quality: do not assume, be aware METPOINT® OCV makes the quality of your compressed air visible

Anyone who warrants quality must be absolutely sure of the performance of his processes

Companies in all branches of industry increasingly have to face major challenges: the more critical consumers become, the more important transparency is in production. Simultaneously, processes are becoming increasingly complex. This particularly applies to the field of compressed-air processing. The more sensitive your products, the higher the requirements placed on the processing of your compressed air. Quality management is particularly demanding where products come into direct contact with the process air.

Even the lowest levels of contaminations can impair process safety and compromise the quality of end products. The persons in charge, therefore, need the surety of reliable quality monitoring.

The METPOINT® OCV detects tiny oil residues in compressed air in the range of one thousandth of a mg/m³ and offers certainty regarding the purity of your compressed air. In this manner, you can meet stipulated standards and can responsibly accept the confidence of your customers.

For more information on METPOINT® OCV please CLICK HERE. For more information on METPOINT® BDL please CLICK HERE and for more information on METPOINT® LKD please CLICK HERE.

MORE FROM THIS COMPANY

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION