|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Automation | >Man and machine: Striking the right balance |

Man and machine: Striking the right balance

22 September 2016

Whilst automotive assembly plants are generally heavily automated, there are still many areas where operators are required. Altec offers solutions that strike an efficient balance between man and machine.

For one particular application for Nissan, a series of dowels and cam brackets must be assembled to a cylinder head before the cam bolts are torqued. These are tasks that would benefit from a semi-automated solution, which would not only improve productivity but also generate a financial payback.

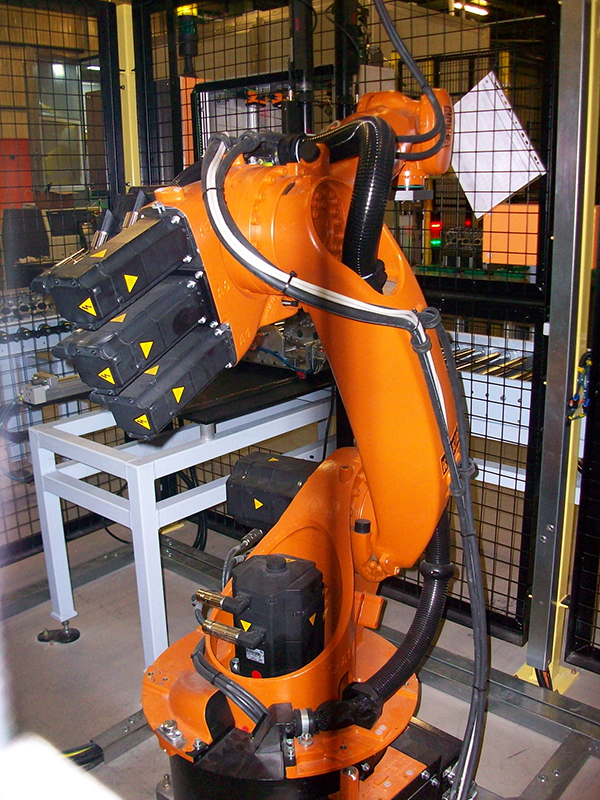

The Altec system comprises two operational stations, linked by a roller transfer system, plus a KUKA robot & Bosch Rexroth nut drivers, all of which are enclosed within perimeter safety guarding, incorporating an operator access aperture protected by a light guard.

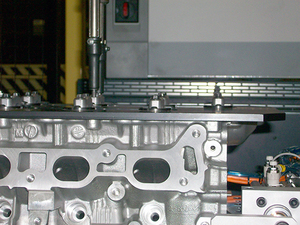

At the first station, the cylinder head is manually loaded onto a base plate, before being located and locked into position on the fixture. A guide plate is placed onto the cylinder head, then 6 dowel pins are located and pressed home using a pneumatic hammer tool. Sensors located on the guide plate are used to detect that the dowels are fully inserted before the cylinder head is released.

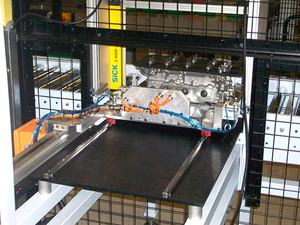

Within the second station, the cylinder head is located on a transfer table where the operator can locate a guide plate to the cylinder head, to allow the correct placement of Cam Bracket and Bolts. Sensors are used to ensure that the correct bracket is fitted for the variant being processed and the table then transfers the cylinder head into the guarded robot cell.

Integrated within the cell is a KUKA KR16 robot which has 2 torquing spindles mounted to the wrist. The robot positions the spindles over the cylinder head and the tightening operations are then initiated. The bolts are tightened in pairs and in a pre-determined sequence, to a mid-torque point to ensure seating and location before being finally tightened to the final torque requirements. The cylinder head is then returned to the operator.

Whilst this application is not particularly complex or demanding from an automation perspective, it proves that there are still areas within even the most highly automated plants where innovative ideas and concepts can bring the benefits of automation to tasks often seen as traditional manual operations. Solutions such as this reduce the number of operators required for the task in hand, freeing up valuable labour for re-deployment in other areas of production.

Stand B10 at the Advanced Engineering Exhibition

- Latest software

- Compact robot controller

- Standard machine elements from Elesa

- test baner

- Baking automation

- Higher payload

- Power supplies controlled via web

- New Eiger freezer door installed as business heats up at leading meat packaging company

- Linear and rotary combination

- High temperature chain fluid