|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Automation | >Optimum combination |

Optimum combination

31 January 2016

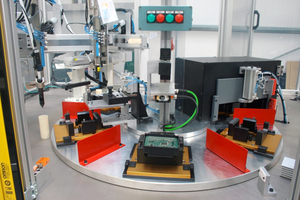

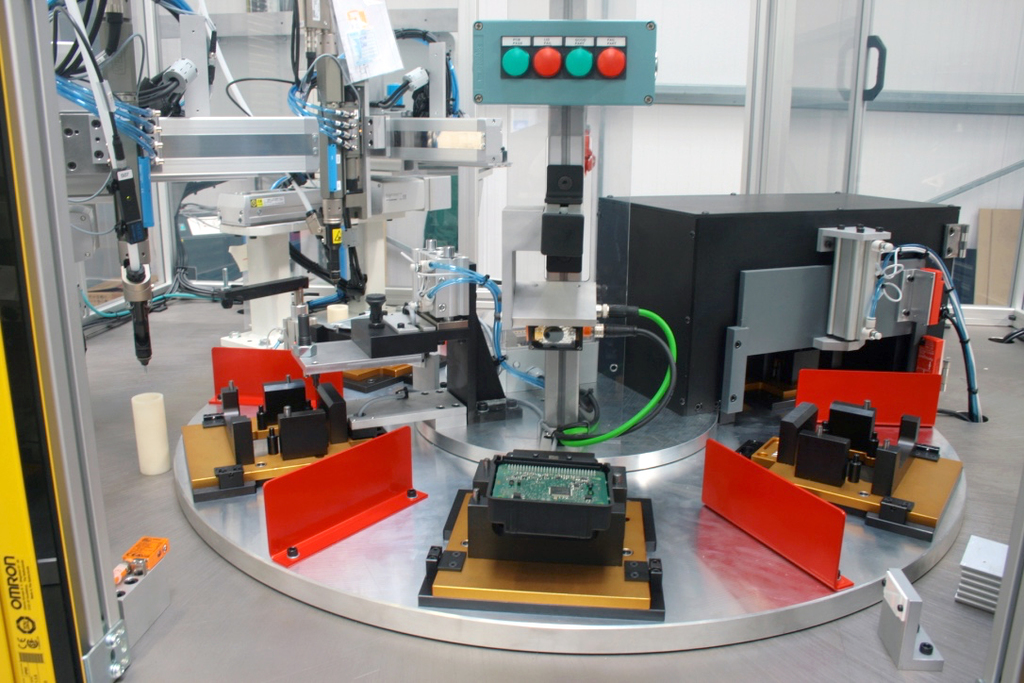

The latest system delivered by Altec Engineering to a manufacturer of automotive engine control units is a good example of how a combination of operator and machine can provide an optimum solution.

The sequence begins with the operator placing a plastic moulded box and populated PCB to the first station on the rotary indexing machine. The 2D data matrix label on the PCB is scanned and the information stored within the PLC data memory.

This information is then picked up via a PC interfaced with the customer traceability system to keep track of the parts as they are assembled. The data is transferred around each station, with the prior step information added for each operation, to ensure the customer has full traceability of each part at any point during the assembly. This feature allows the customer to store process specific data with the 2D matrix code, for future reference.

The operator then loads the lid and presses the start button, initiating a machine vision system operation to verify the presence and correct orientation of the box and lid, before the machine indexes to the first of the automated stations.

This and the subsequent station within the machine, are each used to insert screws, automatically fed from vibratory bowl feeders to the Weber drivers, which check the torque and insertion height as they are being inserted. At a further station a new “Product & Assembly” number is obtained via an Ethernet connection to the customers traceability system and this information is then Laser Engraved in the form of a 2D data matrix code to the assembly. A further index of the machine presents the assembly to a scanner which reads and verifies the 2D data matrix code before the finished assembly is presented to the operator for unloading.

The machine has been designed with future product variants in mind and incorporates quick-change component fixturing on the machine indexing table. The automatic screw driving systems, which each have an integrated Z axis, are also mounted to servo controlled linear drive units to allow them to be re-positioned in X & Y as needed for additional component types.

Now in full production, the machine has reduced the manpower needed to achieve production volumes whilst improving productivity and guaranteeing quality.

- Latest software

- Compact robot controller

- Standard machine elements from Elesa

- test baner

- Baking automation

- Higher payload

- Power supplies controlled via web

- New Eiger freezer door installed as business heats up at leading meat packaging company

- Linear and rotary combination

- High temperature chain fluid