|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cutting systems | >Micro machine debut |

Micro machine debut

29 September 2017

At Advanced Engineering, micro machining specialists Rainford Precision will premiere its new line of Finepart micro abrasive waterjet machine tools.

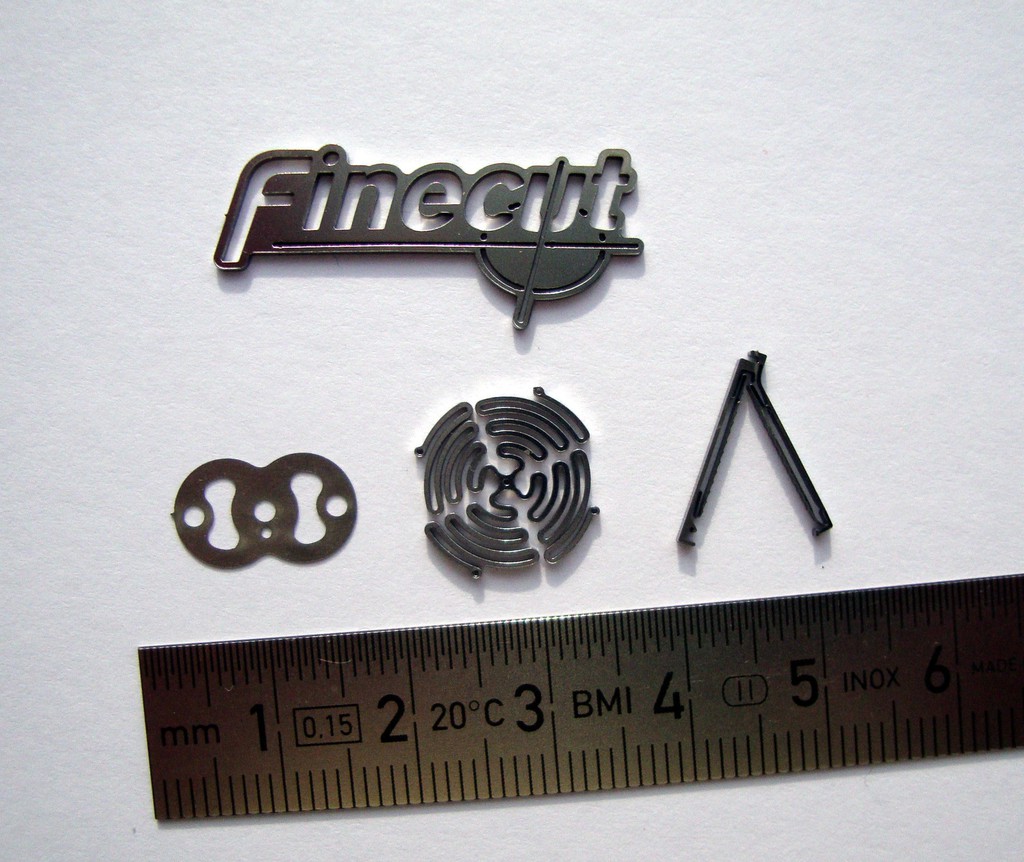

Visitors to the Rainford Precision booth will find a new method of cutting that it is said will solve a raft of issues for aerospace professionals. The company says cutting common aerospace materials such as CFRP, glass, ceramic, aluminium alloys and other advanced materials will become a breeze with the new Finepart waterjet machine. In comparison to conventional methods such as milling, wire or die sink EDM; the Finecut waterjet system eradicates the issue of heat generation through machining. By processing parts without generating high temperatures, the Finepart waterjet series eliminates any structural or metallurgical concerns that are critical for the integrity of the finished part in the aerospace industry.

The Finecut line has a micro-fine jet of just 0.2mm with a positional accuracy of +/-2.5microns and an adjustable jet pressure from 500 to 4000bar. According to Rainford Precision this will provide the aerospace, medical and motorsport industries with a solution that drastically improves precision. Furthermore, it is said to achieve productivity levels superior to conventional EDM methods with flexibility beyond more rigid machine tool configurations.

The Finecut micro abrasive waterjet system has been developed for small to medium size parts with a work area of 500mm by 500mm with a maximum cutting depth of 80mm. The FANUC CNC control system on the Finecut range is a familiar platform for most machine shops, making the new product line an easy to install, simple to set-up, flexible and astoundingly productive machine for processing advanced materials.

Rainford's ranges of drills, end mills, thread mills and circular saws for micro machining and hard material applications from brands such as Iwata, Xactform, Hobe, Louis Belet, Osawa and Union Tool will also be on show. Rainford will also display its comprehensive line of Air Turbine Spindles with spindle speeds varying from 25,000 to 90,000rpm and the KERN range of micro machining centres.

Stand L1