|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Lift trucks & ancillaries | >Explosion protected trucks: What's new? |

| Home> | Health, Safety & Welfare | >Safety Management | >Explosion protected trucks: What's new? |

Explosion protected trucks: What's new?

05 December 2017

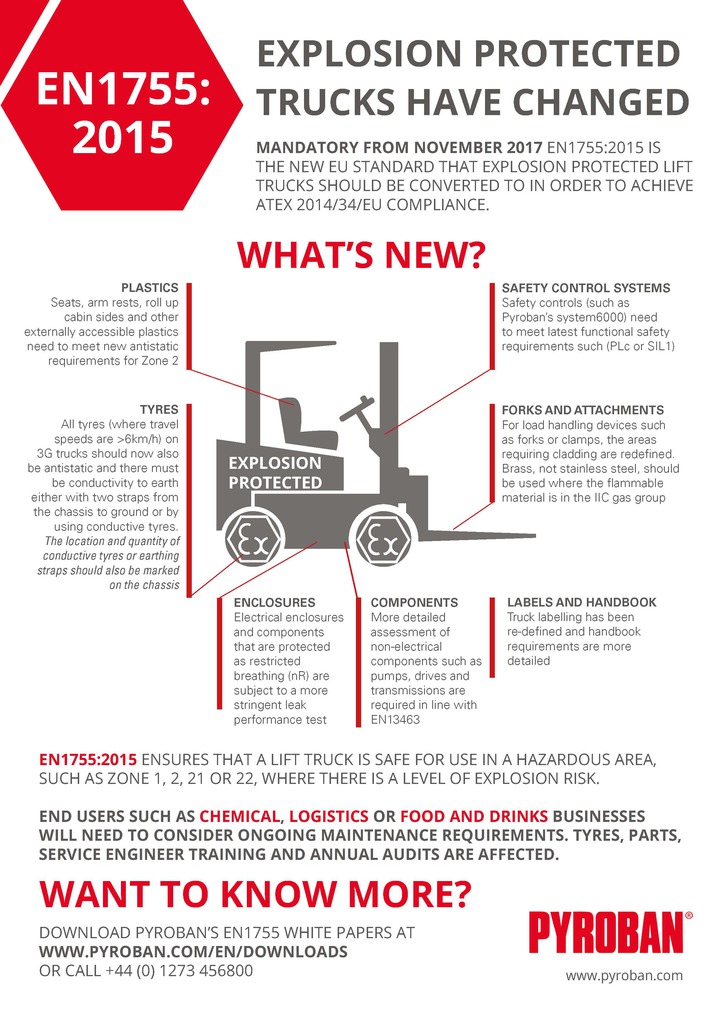

Pyroban has released an infographic to help forklift OEMs, dealers and end users easily understand the effects of the new EN1755:2015 standard on explosion protected lift truck conversions.

“From November 2017, the way explosion protected forklifts, pallet trucks, reach trucks and other materials handling equipment are built has changed due to the EN1755:2015 update,” says Dave Waring, product manager for Pyroban. “The technical requirements have increased to an even higher level of safety and it affects ongoing maintenance requirements.”

It has taken Pyroban almost two years and significant investment to create new solutions and update products to ensure they comply with the new standard and achieve ATEX 2014/34/EU compliance.

“In particular, safety related controls need to meet the latest functional safety requirements in all Zones,” says Waring. “For example, we have achieved this on system6000, our gas detection solution for Zone 2, through PLc in accordance with EN ISO 13849-1. This is now an important factor to consider when specifying an explosion protection conversion on a lift truck.”

New requirements include changes to plastic seats, tyres, enclosure design, assessment and Ex protection of mechanical components and sub-systems (pumps, drives, transmissions) among others.

Pyroban’s EN1755:2015 white paper is available to download.

- EN1755:2015: Driver awareness matters

- Ready for new tyre requirements?

- Explosion protection

- Ensuring safety where there's whisky vapour

- Forklift explosion risks explained

- EU emissions regulations prioritise safety in potentially explosive atmospheres

- New system for Zone 2 Ex

- Providing support for ATEX lift trucks

- Robinson Brothers puts Safety First with Pyroban explosion protection

- ATEX forklift fleet