|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Innovations in roller drive technology |

Innovations in roller drive technology

07 July 2023

Roller conveyors have evolved over the years, with higher weight capacity and the new applications for robotisation, among the requirements which will drive further innovation in MDR technology in the years ahead, says Colin Crowley

THE MOVEMENT of goods using roller conveyors can arguably be traced back as far the building the pyramids in Egypt. Their use burgeoned from the 18th Century when they were employed to load grain onto ships, and for removing coal from mines.

The first patented product in this area was in 1908, and roller conveyors were employed by the Ford Motor company in the manufacture of the Model T and saw broader use from then on, moving products over longer distances.

The evolution of roller conveyors

Since then, innovation in this area has continued to gather pace as specifiers, systems designers have sought solutions which combine efficiency, safety and flexibility across a broad spectrum of applications.

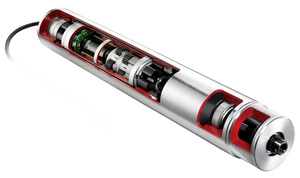

The idea of putting motors into rollers to power them had been around for a while before the first powered conveyor rollers came into use during the 1970s, forming the heart of advanced automated conveyor systems.

This innovation for the first time allowed the possibility of smaller roller zones within an application, rather than having to have a single conveyor across a lengthy area of travel. This means that systems could be installed which used 24V DC power, rather than three-phase power.

These systems were much safer than their predecessors which took the form of gear and chain or sprocket-based solutions which are more complicated to set up, heavier and require the installation of covers to protect operatives working nearby. However, driving rollers by the use of ribbed pulleys made for much easier and more rapid installation and simpler maintenance.

Combining MDR with performant control electronics

More importantly, by combining MDR with performant control electronics, they gave system designers greater flexibility when it came to the positioning of stops and placement points, while ensuring automated distancing between the items being conveyed. This attribute saw motorised drive rollers enjoy increasing use in factory applications as the required control and precision could now be assured.

Another challenge found on production lines is the need to transfer or divert items on conveyors. Manufacturers in these areas have typically offered systems that would require high AC or pneumatic power to operate.

However, continuous innovation by leading players in the sector has resulted in the development of diverter systems based on motorised rollers, which will safely and quickly divert individual loads weighing up to 200kg.

The key benefit here is that these systems will still be able to run off 24V DC power, retaining all the safety attributes of their smaller counterparts.

Grasping the nettle

Robotisation is the other challenge which MDR manufacturers must face. In an increasing number of manufacturing facilities, autonomous mobile robots (AMRs) are now being employed to transport parts around facilities. A typical application would be to fit a short section on top of an AMR, onto which the item must be precisely loaded and positioned. For safety reasons, the item must not move once it is on the AMR and being transported to the next place where it is needed.

This means that the rollers themselves must not rotate, entailing highly effective braking systems. Introduced this year, an exceptionally reliable means of achieving this is the use of specialist mechanical brakes which hold the rollers completely still during transit. This manner of braking is set to become the norm in these application in the future.

Higher weight capacity, and the extension of robotisation into new applications, are the two requirements which will drive further innovation in MDR technology in the years to come - and the leaders in MDR technology are ready to meet that challenge.

Colin Crowley is technical sales engineer UK and Ireland at Itoh Denki Europe

For more information:

Tel: +33 (0)4 50 03 09 99

- No related articles listed