|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Automation | >Pick & place precision |

Pick & place precision

25 July 2018

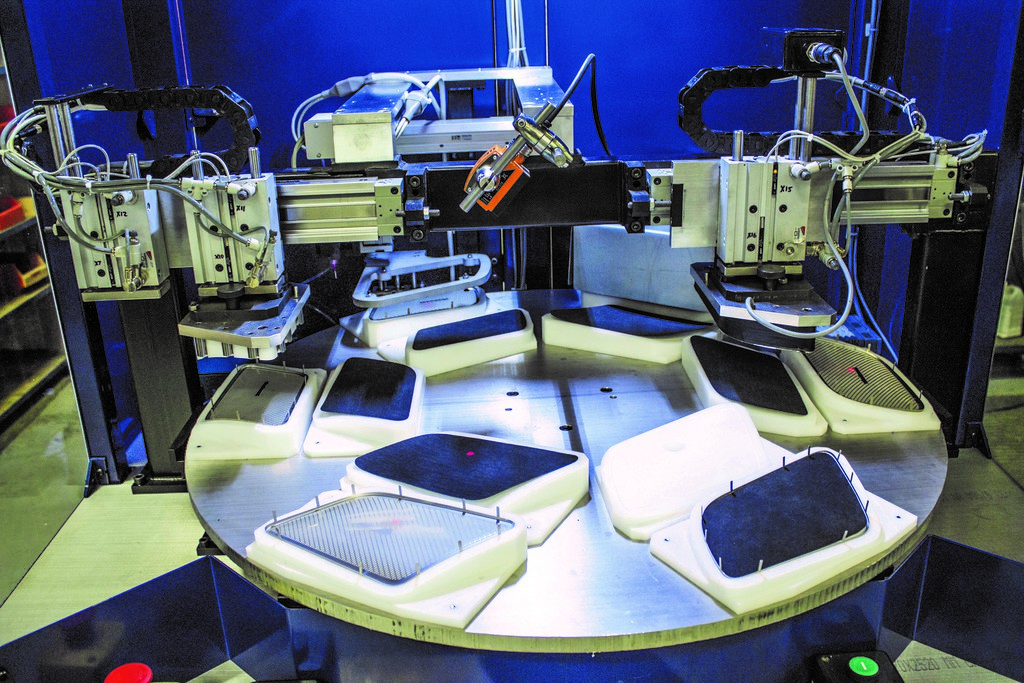

Camozzi Automation’s C_Applications division has employed its Smart Industrial Automation expertise to develop a pick and place unit for use in a car speaker assembly line.

Building upon Camozzi’s panel and systems design and build services, C_Applications integrates electronics, IT, electrics, proportional and pneumatic technologies in complex systems that can be customised to offer intelligent, multi-technological solutions.

The speaker assembly machine performs the task of loading and gluing a grill and felt pad onto a speaker housing unit, an intricate process that was previously carried out by hand, but which was prone to producing reject units.

The bespoke machine was designed from scratch by Tim Lobley, Camozzi’s technical applications manager and comprises six different stations, each carrying out a separate task including placing the pads and grills on the bases, heating and curing the glue and applying controlled pressure to ensure a strong, neat seal is achieved. A camera tracks each stage of the process, before the completed units are transferred to the packing station, where a box label is automatically printed once 6 good units have been produced.

Comments Lobley: “When this process was undertaken by hand it could not meet the volumes required and reject levels were high. Using our automated solution, the customer is achieving a much higher output and the quality of the end product has improved dramatically.”

Employing the expertise available through C_Applications, Camozzi Automation says customers can enjoy tangible cost-saving benefits including improved productivity and reduced assembly and setup times for automatic machines.

- Latest software

- Compact robot controller

- Standard machine elements from Elesa

- test baner

- Baking automation

- Higher payload

- Power supplies controlled via web

- New Eiger freezer door installed as business heats up at leading meat packaging company

- Linear and rotary combination

- High temperature chain fluid