|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Designed for swift assembly |

ARTICLE

Designed for swift assembly

17 April 2013

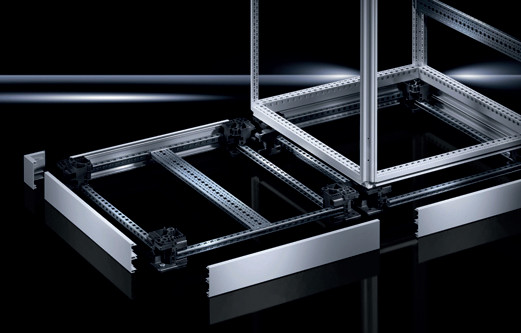

Switchgear assemblers can enjoy time and money savings, says Rittal, by using its new user-friendly Flex- Block base/plinth system. Benefits claimed include fast, more efficient, tool-free assembly of individual components and logistical processes.

Switchgear assemblers can enjoy

time and money savings, says Rittal,

by using its new user-friendly Flex-

Block base/plinth system. Benefits

claimed include fast, more efficient,

tool-free assembly of individual

components and logistical processes.

Rittal's new base/plinth system comprises four identical corner modules and covers made of plastic, plus symmetrical sheet steel side trim panels. The modular design and increased assembly space allow the corner pieces, which support the entire weight of the enclosure, to be quickly and easily fitted underneath the enclosure. Once the enclosure is configured, trim panels are simply clipped into position. Designed for loads of up to 15,000N, the 100mm high corner modules also have hexagonal slots for adaptor sleeves.

Rittal's new base/plinth system comprises four identical corner modules and covers made of plastic, plus symmetrical sheet steel side trim panels. The modular design and increased assembly space allow the corner pieces, which support the entire weight of the enclosure, to be quickly and easily fitted underneath the enclosure. Once the enclosure is configured, trim panels are simply clipped into position. Designed for loads of up to 15,000N, the 100mm high corner modules also have hexagonal slots for adaptor sleeves.

MORE FROM THIS COMPANY

- Rittal Expertise on Show at Maintec 2017

- Quieter cooling units

- Cooling units

- HMIs get some support

- Overcoming enclosure cooling maintenance obstacles

- Housings for TFT monitors

- Energy efficient cooling

- Free cooling equipment survey

- Laser machining centre boosts control panel productio

- Cost effective cooling

OTHER ARTICLES IN THIS SECTION