|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Deburring equipment | >Faster deburring |

Faster deburring

06 September 2016

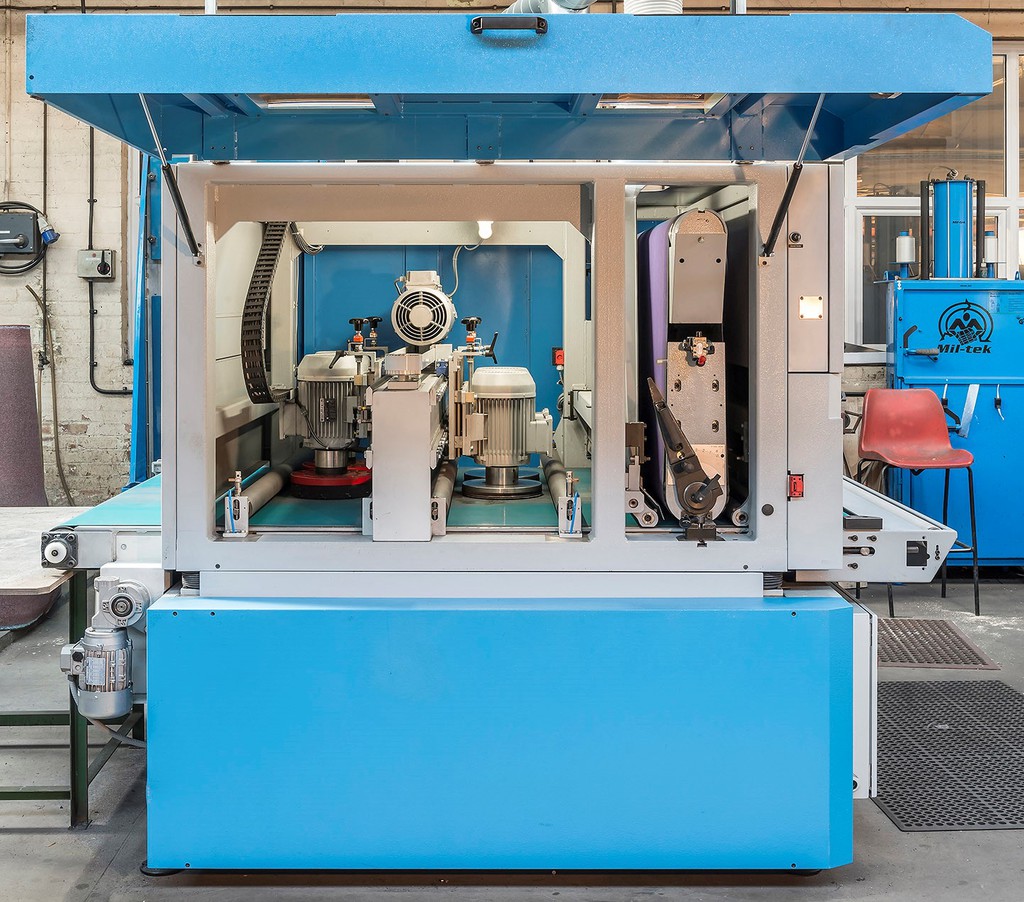

When Cirrus Laser, which laser cuts mild steel, stainless steel, aluminium, rare metals and Mu metal for a variety of industrial sectors, wanted a new machine that would help speed up deburring, edge rounding and surface finishing processes, Engineering Utilities sourced a Loewer K4TD 1350 Beltmaster machine, believed to be the first of its kind in the UK.

The Loewer machine performs deburring, edge rounding and surface finishing processes in one machine and has helped the company to significantly improve its production speeds. The machine is compact, which not only saves factory floor space, but is more energy efficient.

David Connaway, MD at Cirrus Laser, said: “The new Loewer machine has been a valuable asset to our production process, particularly when deburring which was previously done by hand. This now means our experts can increase the capacity and output that we deliver for customers.”

Nigel Soulsby, director at Engineering Utilities, said: “We are always striving to provide the most advanced solutions on the market and constantly seek out new relationships with exceptional suppliers. As part of our exclusive licence with Loewer, we were able to source the new machine for Cirrus Laser, which was custom-built to meet the company’s exact requirements.”

Established in 1976, Engineering Utilities is a second-generation family business spearheaded by the four Soulsby brothers. The Leeds-based company specialises in supplying equipment and consumables for metal preparation, finishing, and cleaning to a diverse range of market sectors throughout the UK and Ireland.