|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Reduces spindle failures |

Reduces spindle failures

28 January 2018

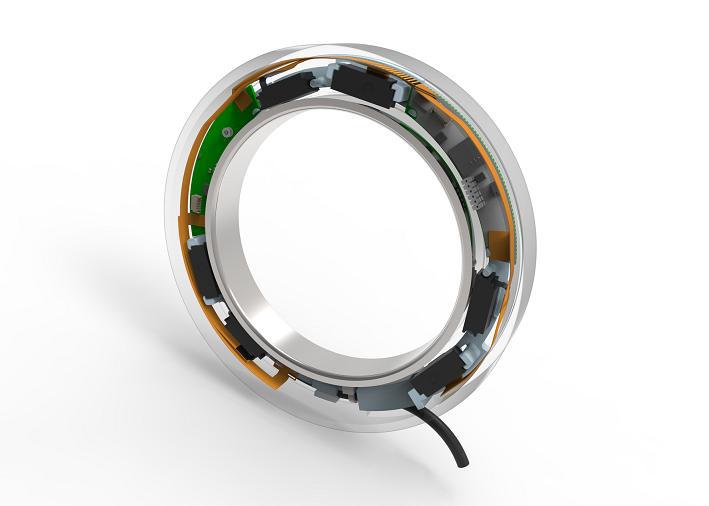

Schaeffler’s engineers have developed a system with the objective of reducing spindle failures by enabling very fast spindle deactivation in the event of a collision. Furthermore, the system allows the machine operator to detect these unfavourable operating conditions and to make targeted adjustments to the machining process.

Another special feature in the age of Cloud computing is that all of the software and the required algorithms are integrated into the sensor technology. This means that the system requires no further components. The system is locally functional and transmits an individual warning signal to the machine’s control system, which makes the following applications possible:

Detecting a crash (collision): the sensor technology is capable of signalling an overload at a digital output within 2 milliseconds. This allows serious subsequent damage to be minimised or even prevented through fast deactivation of the drive.

Long-term protection for machine tool spindles: in practice, continuous mechanical spindle bearing overloads, e.g. when roughing with a worn tool, are not immediately identified. If the system triggers a warning signal in this or a similar scenario, the operator can adjust the machining program right after the first manufactured part and reduce the spindle load by using a new tool or modified cutting values, or by employing a more suitable tool type. The operator therefore achieves lower and less numerous peak loads, and so benefits from a longer spindle operating life with less machine tool downtime, which ultimately means increased production time and reduced repair costs.

The displacement measurement using the sensor ring and the integrated load monitoring has reached the pilot production stage and the first size is now available for customers to test in practical applications. What is more, Schaeffler’s engineers have developed a new analysis tool for optimising the degree of spindle utilisation. With this system, the deflection collective that is measured by the sensor ring during the machining process is visualised over the time axis in addition to a threshold value being defined. For the first time ever, the machine operator will know the degree to which the spindle capacity in each machining process is being utilised as a percentage with a high level of accuracy and therefore will be able to adjust the machining process even more precisely in terms of capacity utilisation and operating life for each machine. This means that harmful overloads are prevented despite high spindle loads. Safe operation in the limit range allows the operator to increase productivity and to also benefit from longer spindle operating life and less frequent machine shutdowns.

- Linear actuators ensure precise positioning of sheet metal parts for transformer cores

- New additions

- Innovations for high precision rotary tables and rotary axes

- Frictional torque reduced

- Measurement device

- Technical pocket guide

- Chance to learn more about bearings

- Versatile monitoring for wind turbine rotor bearings

- Designed for all-electric and hybrid vehicles

- Intelligent lubrication system for bearings