|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Time to warm to cold forming? |

ARTICLE

Time to warm to cold forming?

25 January 2013

Mark Jennings, technical director of Dawson Shanahan, looks at the problem of rising material costs and how different metals and production processes offer a competitive alternative to traditional machining Metal comp

Mark Jennings, technical director of Dawson Shanahan,

looks at the problem of rising material costs and how

different metals and production processes offer a

competitive alternative to traditional machining

Metal component manufacturers have had to cope with a dramatic rise in raw material costs in recent times.

The consensus is that prices will remain high, with copper expected to maintain its strength at just under $8000/t at the close of the year. Considering that prices have already rallied from just above $2800 per tonne in December 2008 to a record high of $10,190 a tonne in February of this year, the potential of copper to command high prices cannot be ignored. This has implications throughout industry, as copper is used extensively in many sectors from power generation and distribution, to automotive and marine. The problem is exacerbated by the fact that copper inventories are falling to their lowest levels.

Many companies who rely on the red metal are left to tackle the quandary of what to do to remain productive, competitive and profitable in such difficult times. For some, the only solution seems to be increasing the price of goods leaving the factory gates. In practice, however, this is not always possible.

With most businesses today running lean operations, there is limited potential for further shaving of costs. Perhaps the most viable options are to consider a switch to lower cost materials, so long as they can ensure that the required characteristics of the finished products can be retained, or to adopt cost effective production methods, such as cold forming.

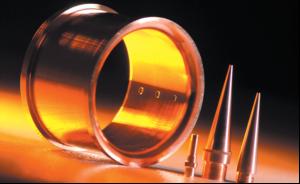

These latter options can deliver benefits to industries using high volumes of copper to produce precision parts and components, especially those using a large quantity of mill supplied Tellurium Copper (CuTE) rods or bars. Although this metal machines well, the processes that have traditionally been used to create the finished parts and components, such as milling, drilling and grinding, usually generate a substantial volume of waste material that adds to costs. For example, machining a typical Tellurium copper nozzle for use in plasma or laser welding applications,with a finished weight of 36g, requires a block of metal weighing 213g from which the shape can be milled. This generates 177g of waste material, over 80% of the total starting weight.At today's prices, this equates to over 85p of wasted material per component.

By comparison, precision cold forming produces minimal waste and typically uses oxygen-free copper wire, which is often more commercially viable than machining Tellurium copper. Oxygen free copper is readily available, so prices are competitive, and generally lower than those of Tellurium copper; as importantly, precision cold forming oxygen free copper produces better results than machining in many applications due to its efficient electrical and thermal properties.

Particularly when it comes to the production of high volume parts, such as bevel, side and pinion gears and steering racks, or smaller volumes of larger components, cold forming represents the most cost effective production method. This technique can produce high quality components, which have good mechanical characteristics and a better surface finish with less scrap - typically up to 80% less than conventional part manufacturing processes.

Indeed, component costs can be reduced by up to 70% in many instances, while lead times can be cut by a similar amount. For instance, to use the earlier example of a copper laser nozzle, only a 54g billet would be needed to produce a fully shaped part that simply requires a minimal amount of final machining, resulting in waste of just 18g or less than 10p in terms of cost.

Essentially, cold forming is the process of producing metal components at low, usually ambient temperatures without removing any material. A simple blank, which has been sawn or cropped from a round bar or wire, or a cold headed pre-form is placed within a die and a punch is applied to the blank. As a result of the force, the blank then takes on the form of the punch and the die.

There are a number of types of cold forming, from forward and backward extrusion through to freeflow. The type of component required should be used to determine the method of cold forming. Through extrusion, drawing or coining, a blank can be made into a wide range of components, segments and assemblies.

As cold forming is performed at ambient temperatures, it is a quicker process than more conventional options, allowing manufacturers to achieve shorter production times. High quality components can be made to order quickly, cutting lead times and the need to store high volumes of spare parts onsite. Production cycle times can be cut further on multi-station machinery, which can be particularly useful in large production runs. Accurate internal profiles and complex external profiles are possible, enabling precision parts to be manufactured that can have a significant impact on the performance of the assemblies and machinery in which they are used.

There is almost no limit to the shape, size or complexity of the metal components that can be produced using cold forming.

Metal component manufacturers have had to cope with a dramatic rise in raw material costs in recent times.

The consensus is that prices will remain high, with copper expected to maintain its strength at just under $8000/t at the close of the year. Considering that prices have already rallied from just above $2800 per tonne in December 2008 to a record high of $10,190 a tonne in February of this year, the potential of copper to command high prices cannot be ignored. This has implications throughout industry, as copper is used extensively in many sectors from power generation and distribution, to automotive and marine. The problem is exacerbated by the fact that copper inventories are falling to their lowest levels.

Many companies who rely on the red metal are left to tackle the quandary of what to do to remain productive, competitive and profitable in such difficult times. For some, the only solution seems to be increasing the price of goods leaving the factory gates. In practice, however, this is not always possible.

With most businesses today running lean operations, there is limited potential for further shaving of costs. Perhaps the most viable options are to consider a switch to lower cost materials, so long as they can ensure that the required characteristics of the finished products can be retained, or to adopt cost effective production methods, such as cold forming.

These latter options can deliver benefits to industries using high volumes of copper to produce precision parts and components, especially those using a large quantity of mill supplied Tellurium Copper (CuTE) rods or bars. Although this metal machines well, the processes that have traditionally been used to create the finished parts and components, such as milling, drilling and grinding, usually generate a substantial volume of waste material that adds to costs. For example, machining a typical Tellurium copper nozzle for use in plasma or laser welding applications,with a finished weight of 36g, requires a block of metal weighing 213g from which the shape can be milled. This generates 177g of waste material, over 80% of the total starting weight.At today's prices, this equates to over 85p of wasted material per component.

By comparison, precision cold forming produces minimal waste and typically uses oxygen-free copper wire, which is often more commercially viable than machining Tellurium copper. Oxygen free copper is readily available, so prices are competitive, and generally lower than those of Tellurium copper; as importantly, precision cold forming oxygen free copper produces better results than machining in many applications due to its efficient electrical and thermal properties.

Particularly when it comes to the production of high volume parts, such as bevel, side and pinion gears and steering racks, or smaller volumes of larger components, cold forming represents the most cost effective production method. This technique can produce high quality components, which have good mechanical characteristics and a better surface finish with less scrap - typically up to 80% less than conventional part manufacturing processes.

Indeed, component costs can be reduced by up to 70% in many instances, while lead times can be cut by a similar amount. For instance, to use the earlier example of a copper laser nozzle, only a 54g billet would be needed to produce a fully shaped part that simply requires a minimal amount of final machining, resulting in waste of just 18g or less than 10p in terms of cost.

Essentially, cold forming is the process of producing metal components at low, usually ambient temperatures without removing any material. A simple blank, which has been sawn or cropped from a round bar or wire, or a cold headed pre-form is placed within a die and a punch is applied to the blank. As a result of the force, the blank then takes on the form of the punch and the die.

There are a number of types of cold forming, from forward and backward extrusion through to freeflow. The type of component required should be used to determine the method of cold forming. Through extrusion, drawing or coining, a blank can be made into a wide range of components, segments and assemblies.

As cold forming is performed at ambient temperatures, it is a quicker process than more conventional options, allowing manufacturers to achieve shorter production times. High quality components can be made to order quickly, cutting lead times and the need to store high volumes of spare parts onsite. Production cycle times can be cut further on multi-station machinery, which can be particularly useful in large production runs. Accurate internal profiles and complex external profiles are possible, enabling precision parts to be manufactured that can have a significant impact on the performance of the assemblies and machinery in which they are used.

There is almost no limit to the shape, size or complexity of the metal components that can be produced using cold forming.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION