|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Electrical components | >Push-in terminal block |

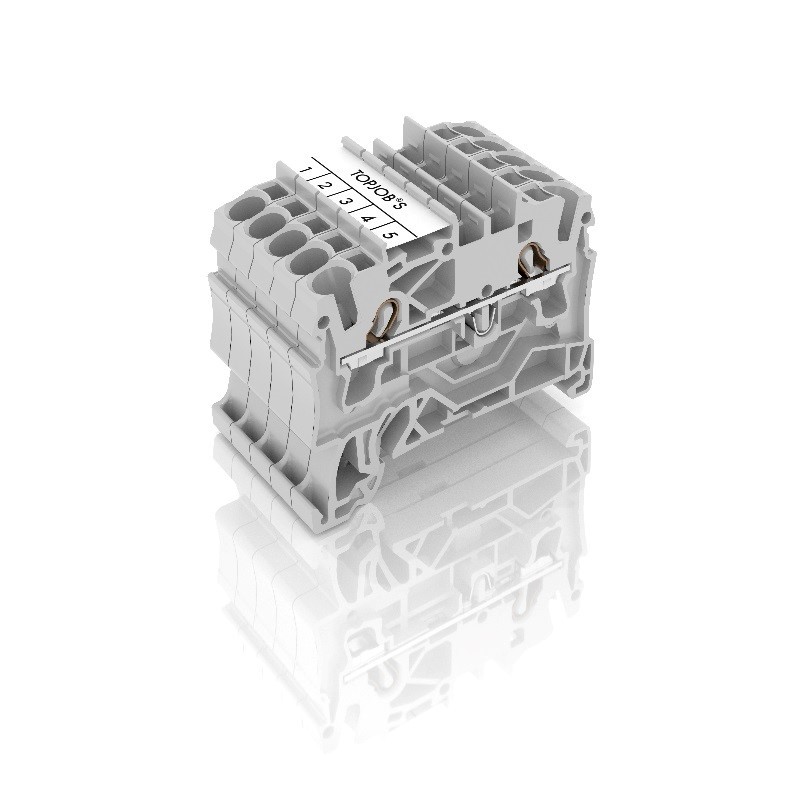

Push-in terminal block

09 June 2016

Reported to be 30% smaller than some competitor products, WAGO’s ATEX-approved TOPJOB S DIN rail-mounted terminal block is suitable for connecting motors, diodes or LEDs in harsh environments from an offshore platform to hazardous atmospheres in the chemical industry.

All conductor types from 0.14 mm2 to 25 mm2 including stripped, solid, stranded and fine-stranded with ferrules, can be pushed into the terminal block using WAGO’s Push-in Cage Clamp technology, thereby eliminating the need to tighten screws.

Proportional clamping means the spring adjusts automatically to the conductor size, so once the wire is pushed in, it is held securely and indefinitely.

For connecting fine-stranded conductors an operating tool is inserted into the slot allowing for hands-free wiring. The tool also helps identify which clamping unit is open. To remove a conductor the tool is re-inserted into the slot.

The product family includes single-, double-, triple- and quad-deck terminal blocks as well as fuse, disconnect and diode terminals. The Top Job S rail mounted terminal blocks enable all of the above conductor types to connect one size greater than their rated cross section. This saves up to 25 percent on wiring space and costs.