|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Boilers & burners | >Ultra low NOx boilers |

| Home> | Energy Management | >Boilers and burners | >Ultra low NOx boilers |

Ultra low NOx boilers

08 February 2017

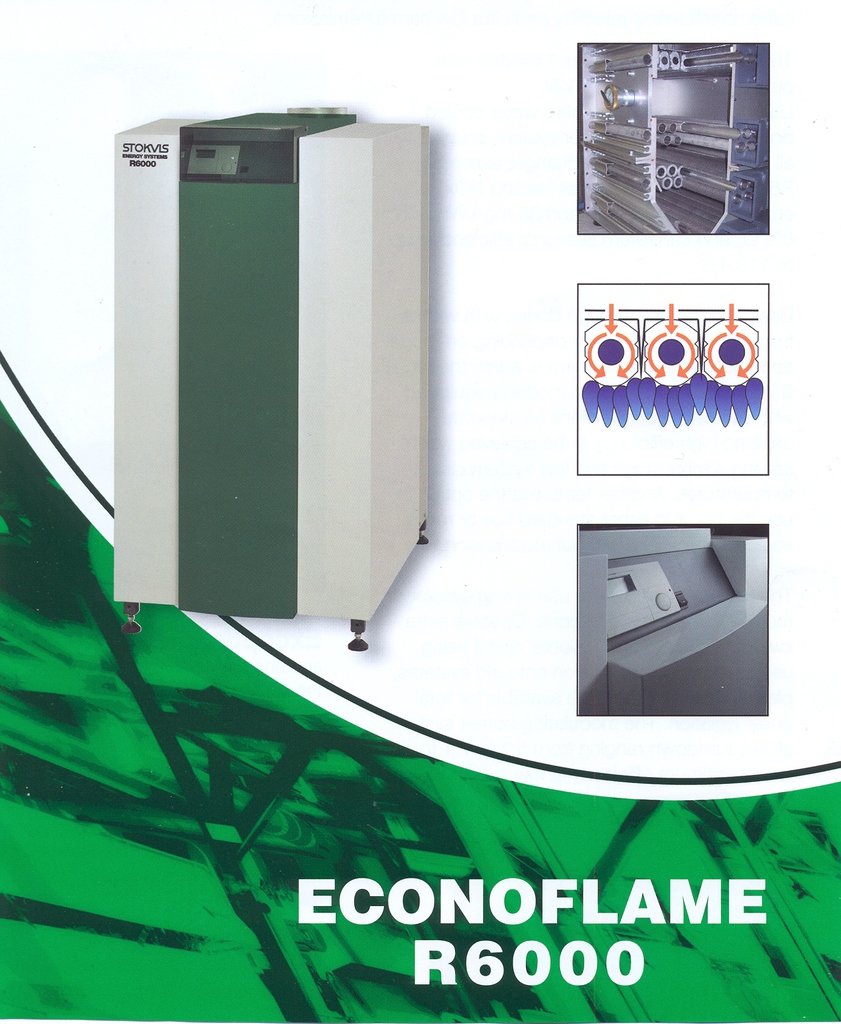

The Econoflame R6000 range of condensing ultra low NOx premix commercial boiler from Stokvis Energy Systems includes seven models with outputs from 142 to 539kW.

Utilising a patented water cooled, down-firing, premix burner system coupled with all stainless steel heat exchanger assembly, R6000 boilers have a NOx emission of between 15 and 35mg/kWh with 0% 02, and can return seasonal efficiencies up to 110.4%.

For easy installation the boilers are designed to pass through doors with widths from 670 to 770mm; floor space requirements are within the range 0.74 to 1.34m2.

Each model has two return connections as standard allowing high efficiency to be achieved when serving a mix of high and low system circuit temperatures. Another feature is the option to use the boiler in either standard flue or room sealed applications without modification.

The R6000 is suitable for use in single boiler or multiple/cascade installations. Optional extra low loss headers are available and if being used in a retrofit application onto old systems, plate heat exchangers are available for total boiler isolation. The modulating burner system allows turndown ranging from 5:1 to 7:1 to return optimum efficiency at low system loads.

A long operational life is ensured through the use of corrosion resistant stainless steel as heat exchanger material, water cooling used in place of insulation and no degradable insulation materials are used.

Hydraulic and safety related options available include plate heat exchangers for system separation, low velocity headers for hydraulic and pump and pressure relief valve kits.

Easy servicing is helped by an inspection hatch fitted in the heat exchanger, which can be used for wash down purposes - no insulation is present.

The R6000 is equipped with a boiler management unit. Besides controlling the boiler and all safety devices connected to the boiler, this unit also takes care of the temperature control of the boiler via an integrated PID controller.

For additional control features, the boiler can be equipped with a heating zone controller.